Benefits

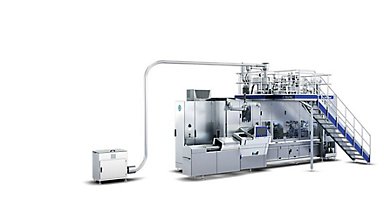

Thanks to the introduction of the Tetra Pak® TT/3 XH IC filling machine you can now make chilled products in modern, convenient Tetra Top packages with even greater flexibility and at lower operational costs.

The new machine brings you extended hygiene for longer shelf life with full food safety. To maximise flexibility and efficiency, it has two separate production lines, capable of filling one or two different products and package formats at the same time. Package volume can be changed in 5 minutes, and you can even rebuild to make different package formats.

Quick facts:

- Package types: Tetra Top® Base / Midi / Mini / MiniV

- Package volumes (ml): 200 – 1000

Applications:

For chilled production of liquid dairy products, plant-based, juice, nectars and still drinks

Features

Dual-line production

Optimise your machine's capacity

Based on a dual-line architecture, which enables running of packages independently on both lines with no need to stop production when cleaning one line.

Extended hygiene (XH)

Ensuring extended shelf life

Tetra Pak® TT/3 XH IC uses the best disinfection solutions available with in-line surveillance to ensure extended shelf life for chilled products. Using proven H₂O₂, UV light (Ultra Violet) and HEPA (clean-air system) technology, this machine offers you top-class hygiene for a stable and robust filling process.

Injection moulding

Adding a convenient opening

This is the world's fastest injection moulding unit. Polythene is injected at high pressure and compressed onto both sides of the carton sleeve. The unit is sealed and water-cooled to provide a sturdy, leak-proof joint that produces lids of consistent quality. The result is a convenient opening. The lid forming unit for the Tetra Pak® TT/3 XH IC filling machine, is supplied with HEPA air to avoid contamination.

Staircase and large platform

Increased operator safety

In line with the latest OHS regulations, the filling machine has a staircase and a larger platform upon which the operators can safely carry out operations such as cleaning, maintenance etc.

Operator interface

Enhanced ease of use

Operator time and complexity is reduced thanks to several smart features. Package Line Monitoring Service (PLMS) enables remote supervision and monitoring of all vital production data. Recipe handling adjusts up to 10 recipes. One operator can easily control features and options via the two Tetra Pak® Operator Panels (TPOP). Line Controller 40 connection enabled.

Process communication via Ethernet enabled.

Application based on Windows 10.

Tetra Top Cleaning Unit (TTCU)

Improved hygiene

The external Tetra Top® Cleaning Unit offers excellent cleaning and disinfection of your hygiene chamber. You can clean and disinfect both sides simultaneously or choose to clean and disinfect one side at a time. One unit is able to clean up to two Tetra Pak® TT/3 filling machines.

Integrated Capping Unit

One Step Opening adds convenience

The Integrated Capping Unit applies a tamper evident cap onto the injection moulded neck inside the machine. This reduces space and maintenance costs while increasing line efficiency and control of cap application.