Features

Effective footprint

Reduces customer system costs

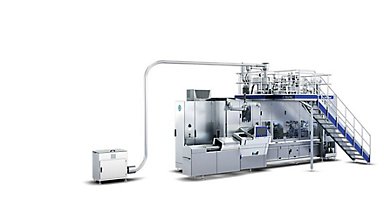

Tetra Pak® A1 for Tetra Brik® has an effective space requirement in relation to the number of packages produced (6.000-12.000 p/h on a footprint of 9,2 x 4,6 m). Space efficiency enhances operational efficiency and helps bring down the overall customer system cost.

Packaging material in-feed and automatic splicing

Long production runs raise efficiency

Each Tetra Pak ® A1 unit holds a jumbo reel of packaging material with sufficient supply for 1h40m of production at the highest speed (20,000 packages). Between one reel and the next, a neat seal is performed automatically so that production can continue uninterrupted.

Automatic strip splicing

Quality splicing

Enables correct, repeatable splicing of longitudinal strip reels, and at the same time makes the operation less labour intensive. The reels are exchanged approximately every 2 hours.

Hygienic system for chilled products

For reliable disinfection of packaging material

The hygienic system for chilled products consists of a shallow hydrogen peroxide bath, squeegee rollers and a heating chamber. The rollers distribute the hydrogen peroxide evenly; controlled heating and evaporation give effective disinfection.

Removed steam barrier and enhanced tube flushing

Low product temperature impact

Product valve steam barrier has been removed and an enhanced tube flushing – higher flow and wider cooling surface – has been added to secure a maximum of 4℃ product temperature increase during filling.

Operator panel

Easy to operate

The production is easily managed through a Tetra Pak Operator Panel on the ground level. All major functions can be initiated and supervised - from production preparation to final cleaning.

Effective footprint

Reduces customer system costs

Tetra Pak® A1 for Tetra Brik® has an effective space requirement in relation to the number of packages produced (6.000-12.000 p/h on a footprint of 9,2 x 4,6 m). Space efficiency enhances operational efficiency and helps bring down the overall customer system cost.