Quick facts

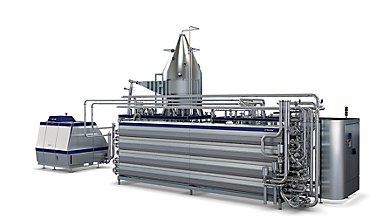

A processing unit for highly efficient, continuous ultra-high temperature treatment of prepared food products. The unit is of aseptic design, and uses a Tetra Pak® Tubular Heat Exchanger for indirect heating to obtain a product that can be stored at ambient temperatures.

Capacity

2,000 – 20,000 l/h depending on the product. Others on request

Applications

Soups, sauces, desserts, fruit preparations, tomato products, baby food and other low or high viscous products with or without particles

Features

Flexible hardware configuration

Product versatility and future proofing

Carefully selected, tested and proven components make it easy to expand and upgrade your system to meet future capacity and production needs. There are also solutions for both your current and your future product portfolios, since the design enables you to process products – aseptic/non-aseptic or smooth/particulate – with a wide range of viscosities.

Optimized heat treatment

Consistently high quality and particle integrity

Components like pumps, homogenizers and deaerators are optimized for consistent stability and texture and particle integrity up to ø 25 mm. Heat treatment is also optimized to ensure quality, and combines efficient heat transfer with short retention times. The design, selection and configuration of your heat exchangers are all flexible.

Hygienic design

Assures food safety

All components are carefully selected for tough operating conditions. Cleaning programmes are designed to assure food safety and optimized production efficiency, and enable you to create unique settings for caustic/alkali, high/low temperature, concentration and circulation time. Advanced automation reduces the chance of human error and enables full traceability.

PLC-based control

To maximize ROI

Our user-friendly PLC-based control gives you full control over recipes and parameters and enables you to make the most of your production plant. You get a good return on your investment, thanks to minimal opportunities for human error, consistent quality, high throughput and lower costs. Take control a step further with our Tetra Pak® PlantMaster supervisory system for control rooms, giving you the convenience of flowchart overviews, product routing/selection, advanced data logging, automated reporting, full traceability and easy preventive maintenance.

Automated and optimized emptying and filling

Reduces product waste

Due to automation, the emptying and filling functions are very precise. A control system measures the concentration of product to water much more accurately than is possible with manual operation. The reduction in product waste, and consequent cost savings are dramatic. We’ve calculated that producers can save between €17,000 – 35,000 per year – assuming four product changes at a revenue of €1/litre product.