Features

Optional use of eBeam

Chemical-free packaging material disinfection

- Tetra Pak® E3/Flex XH is for the production of chilled products with an extended shelf life. A single eBeam lamp is used to disinfect the inner part of the packaging material. Start here and switch easily to chilled production via the operator panel.

- Tetra Pak ® E3/Flex Pasteurized is for the production of short shelf life chilled products. No eBeam lamp is needed to disinfect the packaging material. Start here and switch to ESL production by installing the Optional Kit Adaptation For Extended Hygiene.

New servo toolbox for DIMC

Controlled moulding movements

The Direct Injection Moulding Concept (DIMC) station on Tetra Pak® E3 Flex platform is activated by a motor driven tool box instead of a pneumatic cylinder. The Servo Toolbox guarantees a controlled movement in terms of moulding position and moulding closing torque.

Web Position Active Control

Enhanced sealing quality and reduced dust

This new feature improves two important aspects of the filling machine functionality:

- Sealing quality because the web position accuracy is improved through a dynamic correction of the position

- Reduced dust because the device is not in contact with the edges of the packaging material

Tube Position Active Control

Automatic adjustment in packaging material positioning

This new feature reads the rotations of the packaging material during transient phases and corrects the creases alignment of the package. It enables the Web Position Active Control to make adjustments automatic.

New operator interface

Wide screen

The operator panel has a new look and feel and a wider screen – in 16:9. More intuitive icons are available with added functionality and improved usability. The time required to perform the different operations has been reduced.

Breakthrough eBeam technology

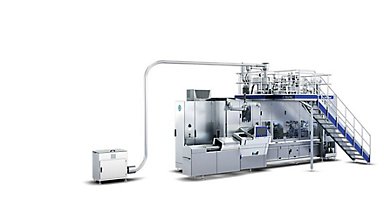

The Tetra Pak® E3 platform is a series of filling machines that use eBeam technology to sterilise packaging material replacing the traditional hydrogen peroxide sterilisation process for packaging material while guaranteeing the same sterilisation performance. The eBeam sterilisation technology works by focusing a controlled beam of electrons on the surface of a packaging material to kill micro-organisms as it runs through the filling machine.

View video and find out more

Breakthrough eBeam technology

The Tetra Pak® E3 platform is a series of filling machines that use eBeam technology to sterilise packaging material replacing the traditional hydrogen peroxide sterilisation process for packaging material while guaranteeing the same sterilisation performance. The eBeam sterilisation technology works by focusing a controlled beam of electrons on the surface of a packaging material to kill micro-organisms as it runs through the filling machine.

View video and find out more

Benefits of eBeam technology

eBeam

Reduce operational cost

The new sterilisation technique offers numerous advantages such as higher production capacity with no increase in machine dimensions. The Tetra Pak® E3/Speed Hyper filling machine is able to reach 40,000 portion packs per hour, a more than 60% improvement compared with our existing Tetra Pak® A3 platform. In this way, you may save up to 20% in operational cost due to improved efficiency.

Breakthrough technology

Tetra Pak® E3, a filling machine platform bringing the breakthrough technology eBeam to the beverage carton industry for the first time. eBeam replaces the traditional hydrogen peroxide (H2O2) sterilisation process for packaging materials.

eBeam

Improve environmental performance

The use of the eBeam system instead of hydrogen peroxide means fewer chemicals need to be stored and treated, leading to reduced consumption of water and energy. The continuous operation of eBeam reduces the packaging and product waste that happens during the set up for the hydrogen peroxide sterilisation process, allowing you to improve your environmental performance.

Production flexibility

The new platform allows for higher modularity in terms of filled product types. Thanks to eBeam technology, you can use the same machine to move from pasteurised filling to extended shelf life production.

Electron beam technology for carton packaging material sterilization