Features

Best-in-class hygiene

Secured food safety and protect operators

1. New dedicated closure peroxide spray secures food safety

2. Controlled peracetic acid dosing system

3. Temperature sensor helps secure hygiene

4. Improved staircase and railings

5. Emission control system

Magazine

Self-supervision of magazine synchronization and vacuum minimizes downtime

The status of moving components is visible in a status bar on the operator panel, enabling faster troubleshooting. And the fast and ergonomic loading is still an important part of the design.

Bottom folding and sealing

Strong, stable and tightly sealed

The temperature-controlled heaters and mandrel tops, combined with a long cooling period, result in strong bottom seals and very low risk of pinholes – all contributing to high product safety.

Cap and carton disinfection

Secure food safety over the desired shelf life

To ensure consistent cleaning and disinfection, we have introduced a dedicated cap disinfection spray. Each cap is sprayed with hydrogen peroxide (H2O2) to improve hygienic. Hydrogen peroxide is also applied inside the cartons before hot air removes all hydrogen peroxide to an undetectable level.

Fill system

Greater safety, lower costs

With a fill accuracy up to ± 1 gr (actual standard deviation 0.5 gr), the double diaphragm system allows you to fill accurately and consistently, minimising over-filling. A controlled, sterile environment and an automatically closing lid -which shuts during cleaning and intermediate stops - makes the system both safe and efficient.

Top sealing

High performance with tight seals

The mechanically driven top sealers in stainless steel are engineered for consistent performance with strong, reliable seals that don’t leak.

Integrated Cleaning System

Best-in-class food hygiene

Compared to manual cleaning, this efficient, automated cleaning system achieves better results, while consuming less energy, utilities and chemicals. New steam traps improve steam sterilization efficiency. And the automatic peracetic acid dosing and flow system, with new flow meters, regulates critical parameters.

Cap applicator (optional)

Low noise and high performance

The integrated applicator is suitable for both the TwistCap and TwistCap Barrier closures. Since the caps are sealed ultrasonically, you can count on a tight, accurate seal at high speed, which helps protect the filled product.

Patented new emission control system

Protect operator safety

The new emission control system reduces emissions from the filling machine to below the limit of 0.5 ppm. To achieve this, several suction points collect air from inside the machine, break down the emissions and release clean air above the machine – thus eliminating the need for an exhaust outlet in the roof. The system also helps remove particles in the air, such as paper dust.

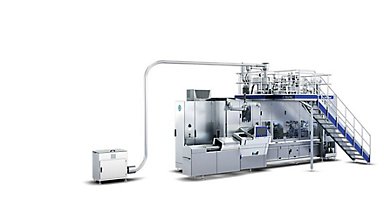

Tetra Pak TR/28 XH optimised filling

The Tetra Pak patented filling technology, Optimised filling, eliminates issues like splashing, foaming and air incorporation during filling. It thus increases hygiene, lowers waste and boosts machine output.

Optimised filling is a standard feature of our latest Tetra Pak® TR/27 XH and Tetra Pak® TR/28 filling machines. In addition, Optimised filling kits have been implemented on all existing Tetra Pak TR/27 and Tetra Pak TR/28 filling machines which are under ten years old

Tetra Pak TR/28 XH optimised filling

The Tetra Pak patented filling technology, Optimised filling, eliminates issues like splashing, foaming and air incorporation during filling. It thus increases hygiene, lowers waste and boosts machine output.

Optimised filling is a standard feature of our latest Tetra Pak® TR/27 XH and Tetra Pak® TR/28 filling machines. In addition, Optimised filling kits have been implemented on all existing Tetra Pak TR/27 and Tetra Pak TR/28 filling machines which are under ten years old

Optimised filling white paper

Thanks to the development of the Tetra Pak patented technology optimised filling we are able to offer our customers a superier filling solutions for gable top carton packages. Sign-up and learn more about optimised filling.