Tomato products – purée, paste, ketchup and sauces

Tomatoes provide a good source of vitamins and minerals, are low in calories and high in carotenoids, beta-carotene and lycopene. Recent research shows that when processed, tomatoes have even higher levels of lycopene, which is one of the most powerful natural antioxidants.

Tomato products – purée, paste, ketchup and sauces

Tomatoes provide a good source of vitamins and minerals, are low in calories and high in carotenoids, beta-carotene and lycopene. Recent research shows that when processed, tomatoes have even higher levels of lycopene, which is one of the most powerful natural antioxidants.

WHAT OUR SOLUTIONS DO FOR YOU

In the last twenty years, there’s been an explosion of new and refined processed tomato products. Purées and passata have become major products together with ketchup, tomato paste, whole peeled tomatoes, chili sauce, pizza and pasta sauces. Consumers simply love tomatoes.

1. IMPROVE PERFORMANCE

Fine-tune your homogeniser to boost quality of tomato products

2. FUTURE-PROOF PRODUCTION & TRENDS

3. LINE SOLUTIONS & KEY ENABLERS

Best-practice Line Solutions for Tomato Products

Best-practice Line Solutions

Our optimal solutions unleash your innovation and enable you to produce a wide range of tomato products – from passata, purées, paste, salsa and pizza sauces to soups and ketchup – with competitive and guaranteed performance, to meet your needs for cost-effective and versatile production. We enable your flexibility in packaging and processing options, whether it is for chilled or ambient distribution.

Download – Best-practice lines for tomato productsBatch Line Tomato Preparations

This line handles smooth to small particulate products. It allows you to produce a greater variety of products, from smooth sauces to crushed or diced component sauces. It enables batch production with a stand-alone processor capable of cooking with direct or indirect heating and cooling. It also enables texturisation of tomato products for particle standardisation while enabling incorporation of small particles, such as cubes. The recipe-specific shear rate in mixing, gentle blending of particles and optimal heat treatment achieves the desired product characteristics. Our line enables production with exceptional quality and efficiency.

Download PD leaflet - Tetra Victenso™ batch lineBatch Particulate Tomato Preparations Line

This line handles particles up to Ø25 mm with excellent particle integrity. It allows you to produce a greater variety of products with excellent texture – from smooth passata to crushed or chunky component products, such as salsa – that taste natural and homemade. Gentle processing prevents the breakdown of particle shape and maintains even distribution. The recipe-specific shear rate in mixing, gentle blending of particles and optimal heat treatment achieves the desired product characteristics. Our line enables production with exceptional versatility, quality and efficiency.

Download PD leaflet - Tetra Victenso™ batch particulate line Continuous Tomato Preparations Line

This line handles production of smooth to small particulate tomato sauces and pastes. It allows you to produce a broad range of tomato preparations – natural products with more tomato content, less sugar, and fewer additives – that taste natural and homemade. The recipe-specific shear rate in mixing and optimised heat-treatment achieves the desired product characteristics. Our line enables safe production with exceptional quality and efficiency.

Download PD leaflet - Tetra Victenso™ continuous line Continuous Particulate Tomato Preparations Line

This line handles particles up to Ø25 mm with excellent particle integrity. It allows you to produce a greater variety of tomato preparations that taste natural and homemade – from smooth to chunky and with more tomato content, less sugar and fewer additives. The recipe-specific shear rate in mixing, gentle blending of particles and optimised temperature program achieves the desired product characteristics. Our line enables safe production with exceptional versatility, quality and efficiency.

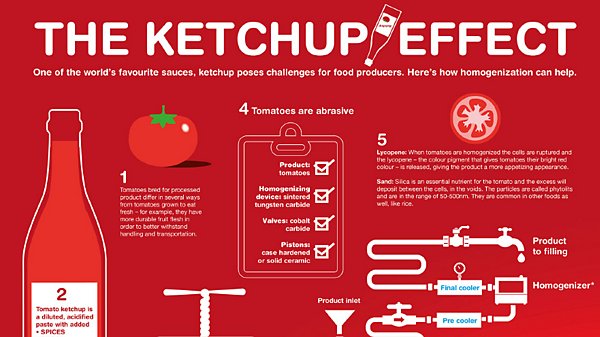

Download PD leaflet - Tetra Victenso™ continuous particulate line Line Solution Key Enabler: Homogenizer

Tetra Pak® Homogenizers

Pioneering design for lower pressure and energy savings with smart automation

Tetra Pak® Homogenizers reduce particle size and improve product quality. Available in non-aseptic and aseptic versions with a wide range of capacities and pressures, and for products with different viscosities.

Capacity: 55 l/h to 63,600 l/h

Cost Effective Maintenance: Lowest operational, utility service and spare parts costs

Operational Efficiency: Highest homogenizer uptime

Applications:Efficient homogenization of both low and high acid products; wide range of applications

Tetra Pak® Homogenizers for high performance

For years, Tetra Pak's homogenizers have been enabling the most cost-efficient homogenizing on the market. In recent years, we have built on our own pioneering design and engineering excellence to create a new generation of homogenizers that increase cost efficiency and reduce environmental impact without compromising food safety.

Features

• Easy to inspect & safer for operator with the large inspection window

• Robust pump block with 10-year warranty against cracks

• Turnable parts – doubles the lifetime, half the cost of spare parts

• Openable hoods, doors and panels for easy way access servicing

• Designed for high capacity at low rpm to ensure lower wear, longer service intervals and wider safety margins

Options

• Automatic damper: For longer running times

• Smart automation system to provide you full control of homogenization

• Removable modular design: For fast service and easy access to cut downtime