Whey processing applications for whey powder

Traditionally, whey was regarded as a useless by-product of cheese production. Now, thanks to the development of industrial methods like centrifugation, filtering and spray drying, it has become possible to produce a variety of very pure whey derived powders. Whey processing for deriving these powders can be made efficiently on a large scale for use in applications requiring very high levels of food safety. All this, combined with a deeper understanding of its nutritional value, means that whey is today regarded as an equally high-value ingredient as the curds.

Whey water recovery

The high water content of whey (94%) poses challenges in the dairy industry. Reverse osmosis (RO) effectively removes water from whey, reducing the need for fresh water and streamlining transportation, leading to cost savings and environmental benefits. Watch the video to learn more.

Download here to read more how to add value to your whey with membrane filtration

Whey water recovery

The high water content of whey (94%) poses challenges in the dairy industry. Reverse osmosis (RO) effectively removes water from whey, reducing the need for fresh water and streamlining transportation, leading to cost savings and environmental benefits. Watch the video to learn more.

Download here to read more how to add value to your whey with membrane filtration

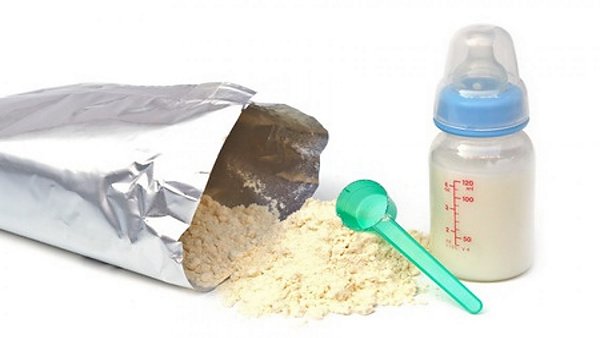

Customer case: Making the most of whey

Mammen Dairies, a leading cheese producer, has partnered with Tetra Pak to implement a reverse osmosis membrane filtration system to efficiently concentrate whey protein from cheese production. This valuable by-product is now being transformed into a key ingredient for infant formula and sports nutrition drinks.