This page complements our Sustainability Report FY23. The report was prepared using the European Sustainability Reporting Standards (ESRS) to structure our sustainability statements and to provide an overview of Tetra Pak's sustainability performance for the period 1 January 2023 - 31 December 2023.

Find our Sustainability Report FY23 here

Circularity and resource use

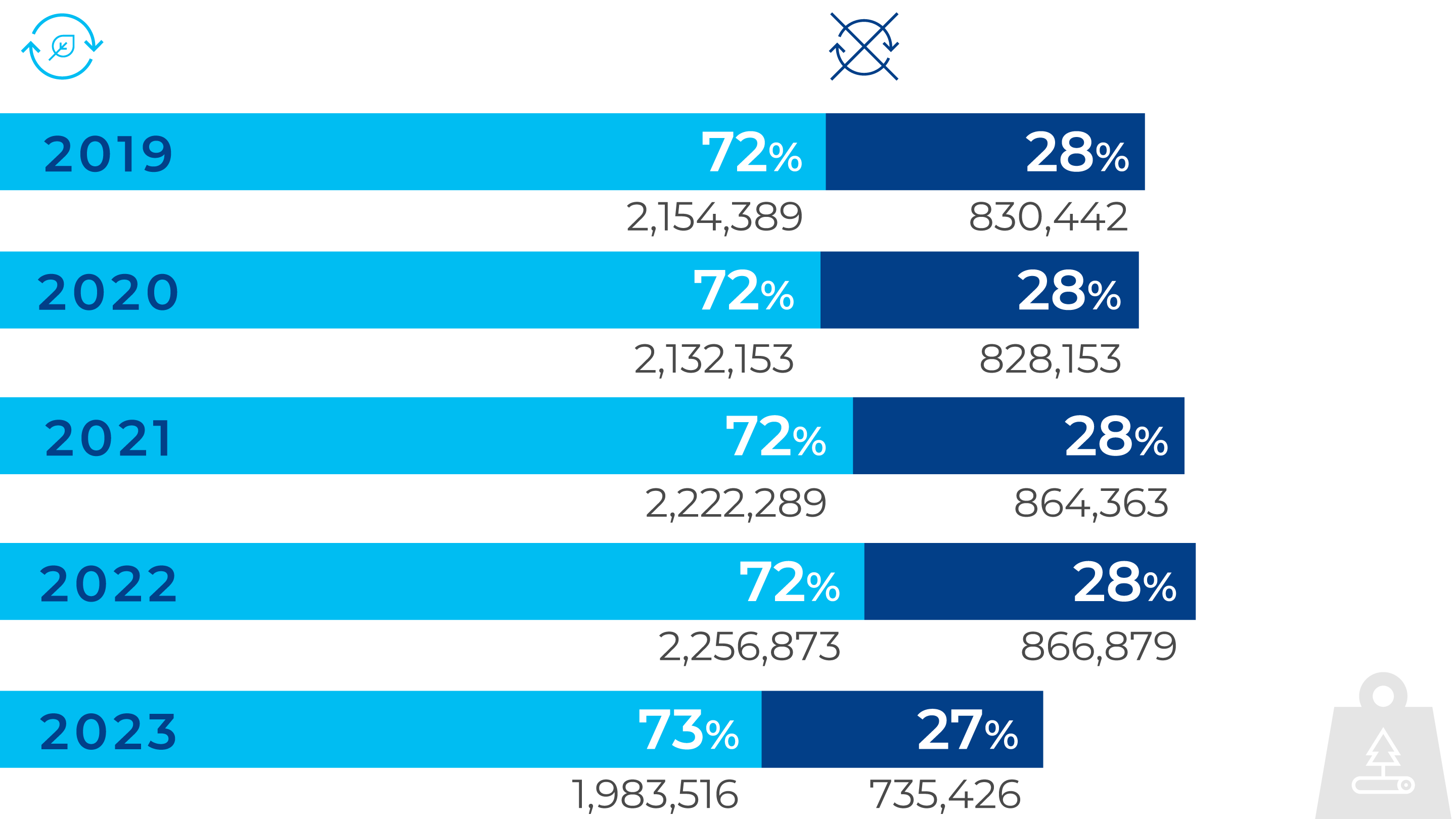

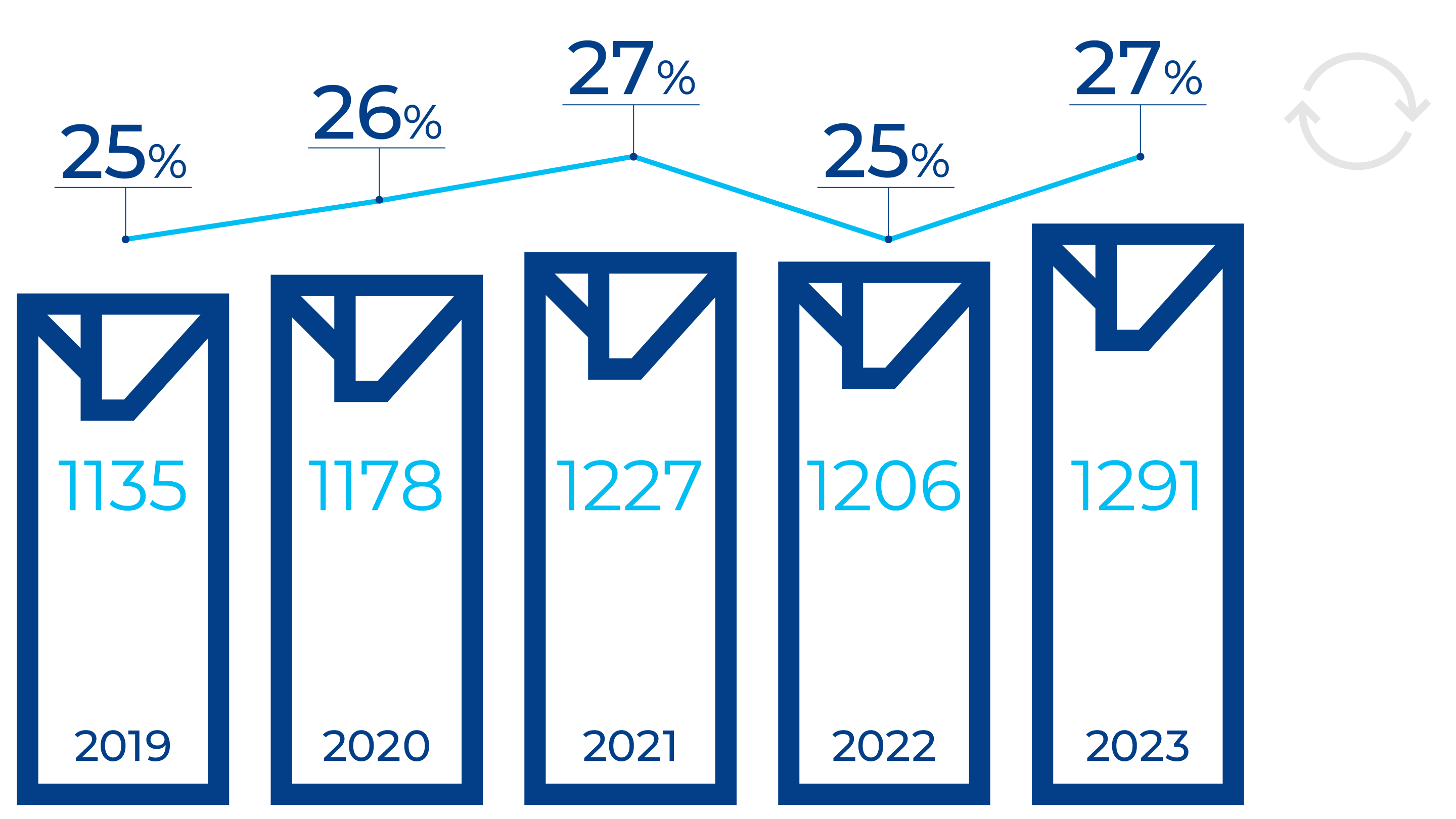

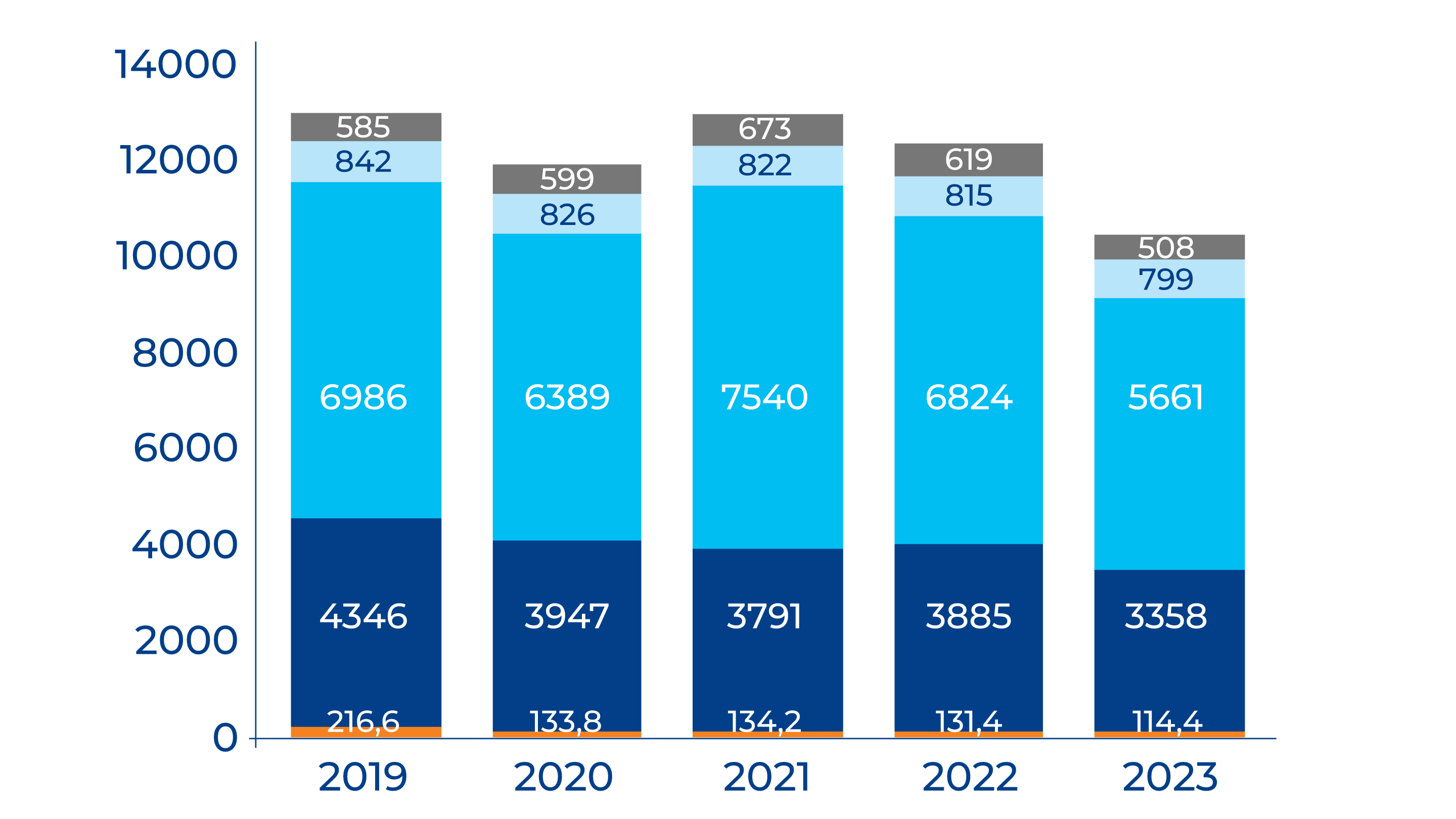

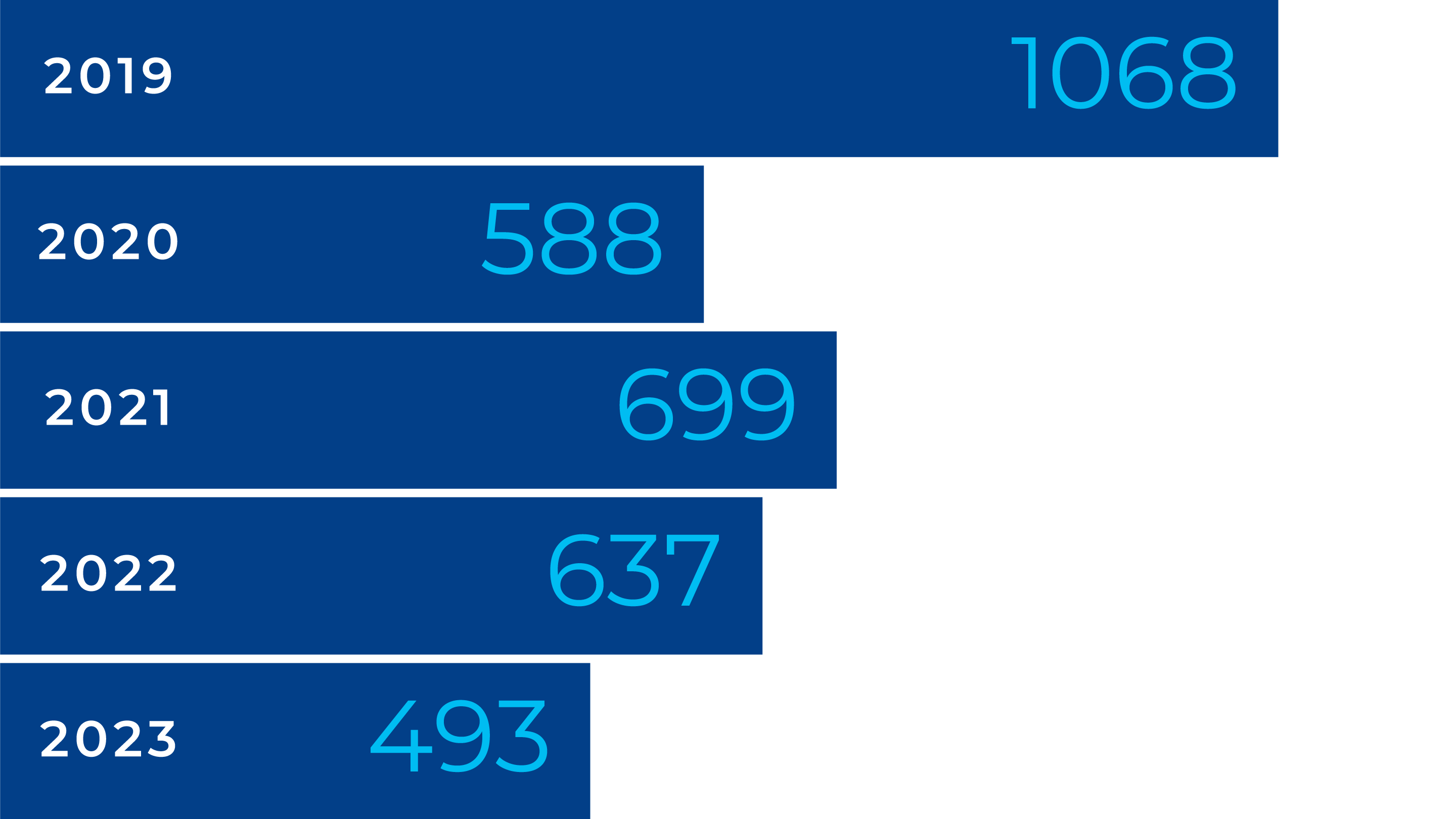

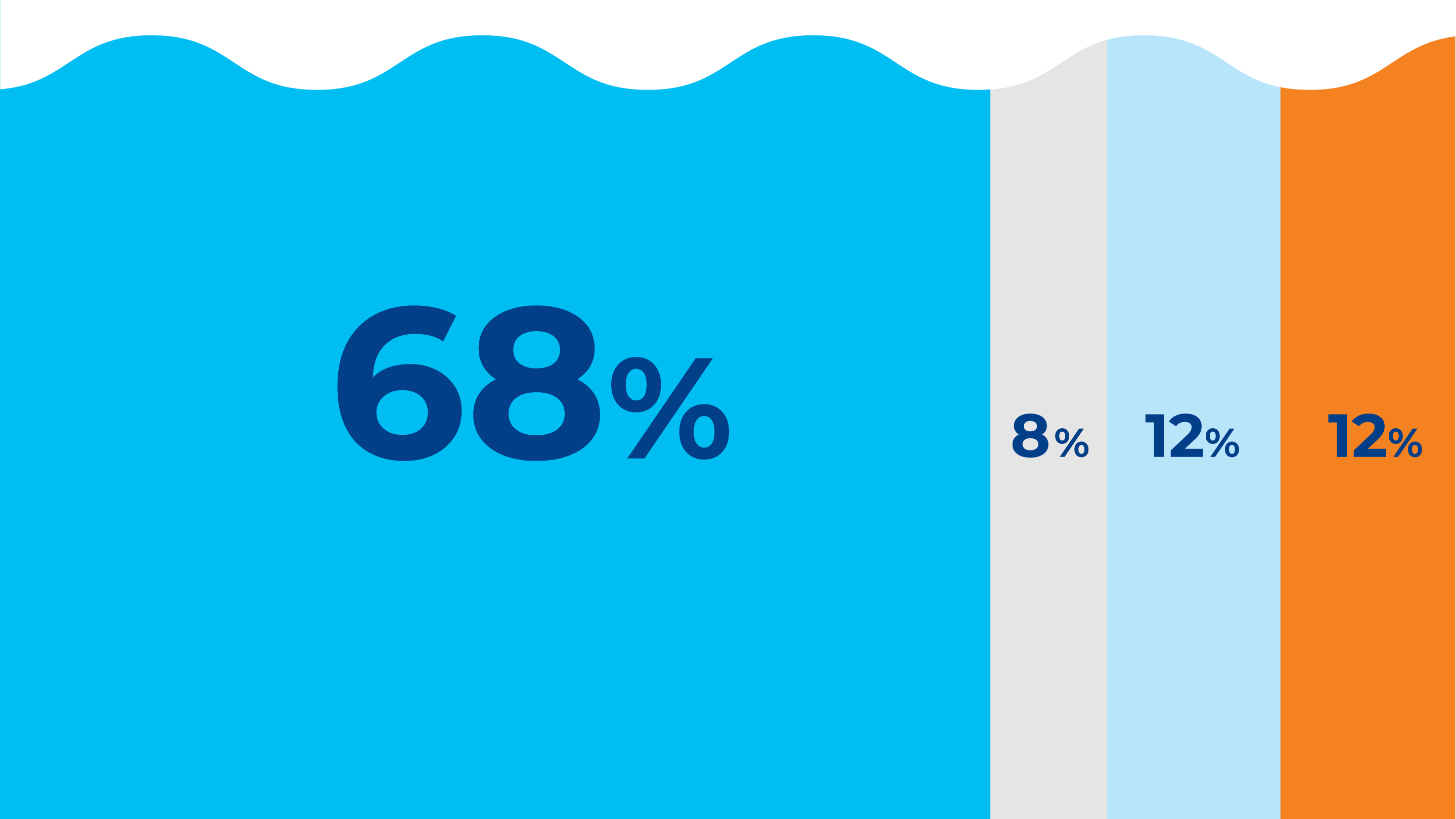

Carton package recycling volumes & rates

We collect recycling data from all markets we operate in worldwide. The reported used carton package recycling rate is based on the share of cartons collected and sent for recycling versus cartons deployed. We use official publicly available data from renowned sources such as governmental agencies, registered recovery organizations, nationwide industry associations and NGOs. Information is reported on a regular basis using a consistent approach. In case of missing information, we refer directly to data from recycling and/or collection partners with inputs from our local sustainability teams to make sure to have the broadest possible set of data.

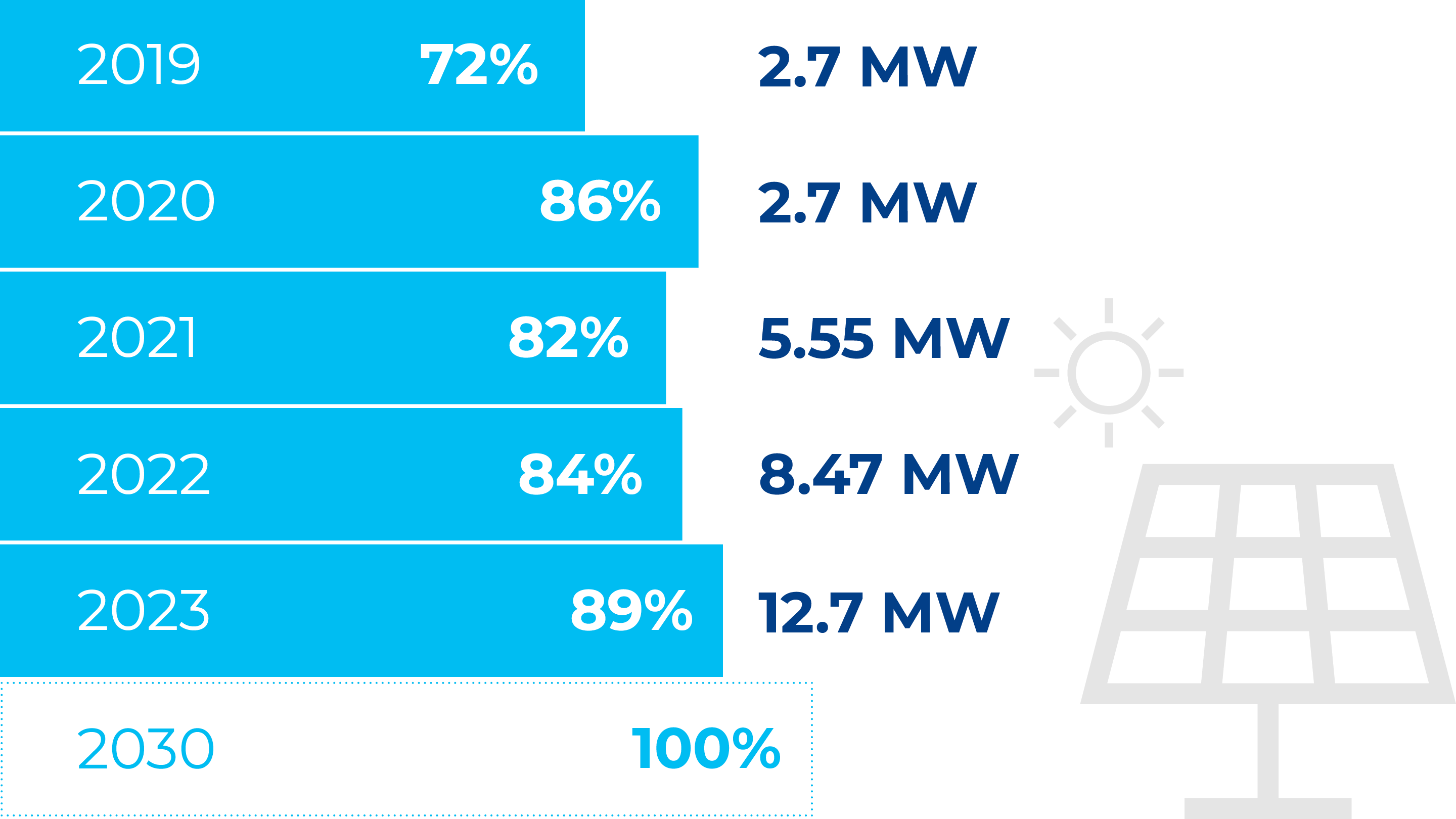

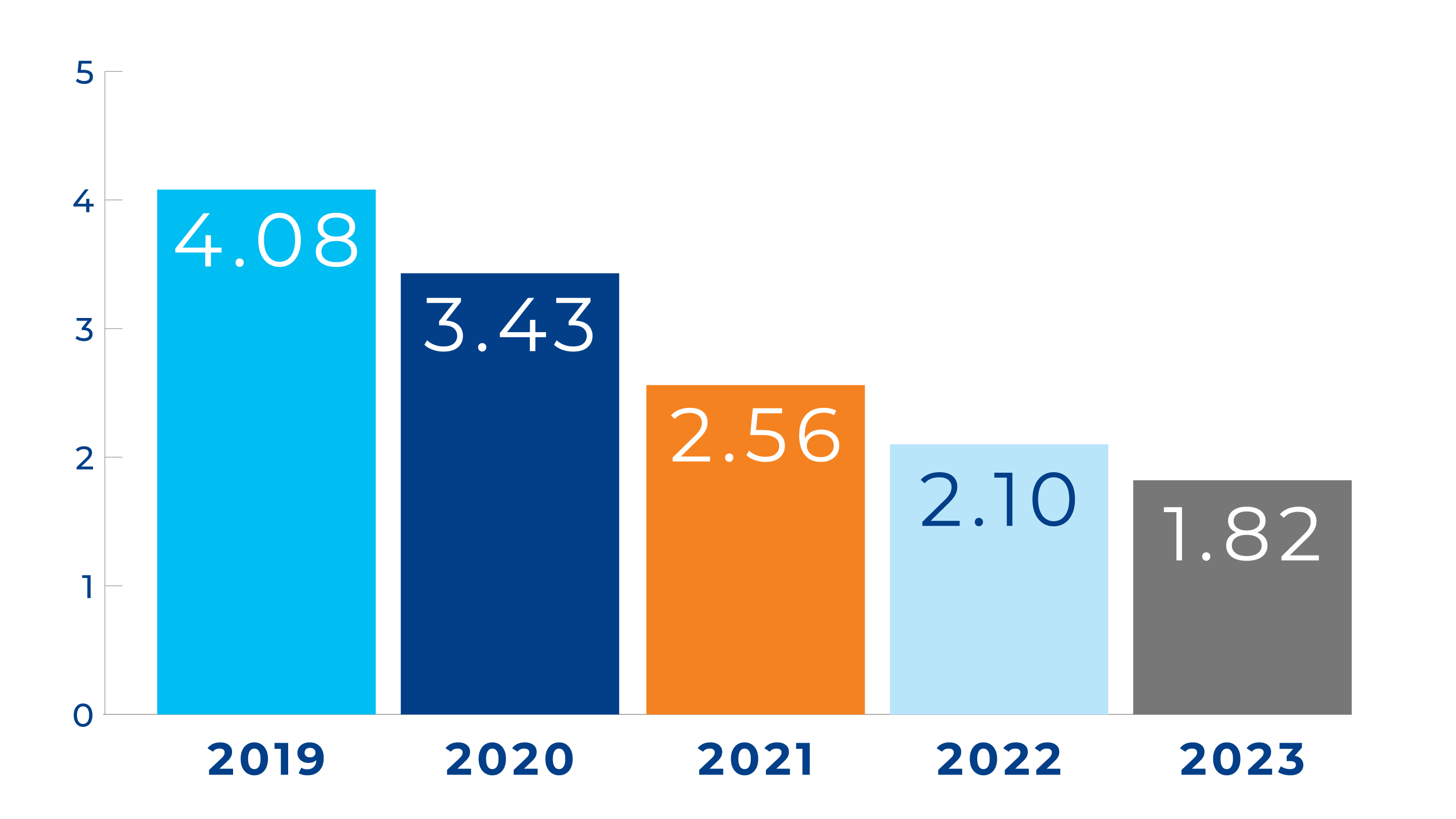

Climate

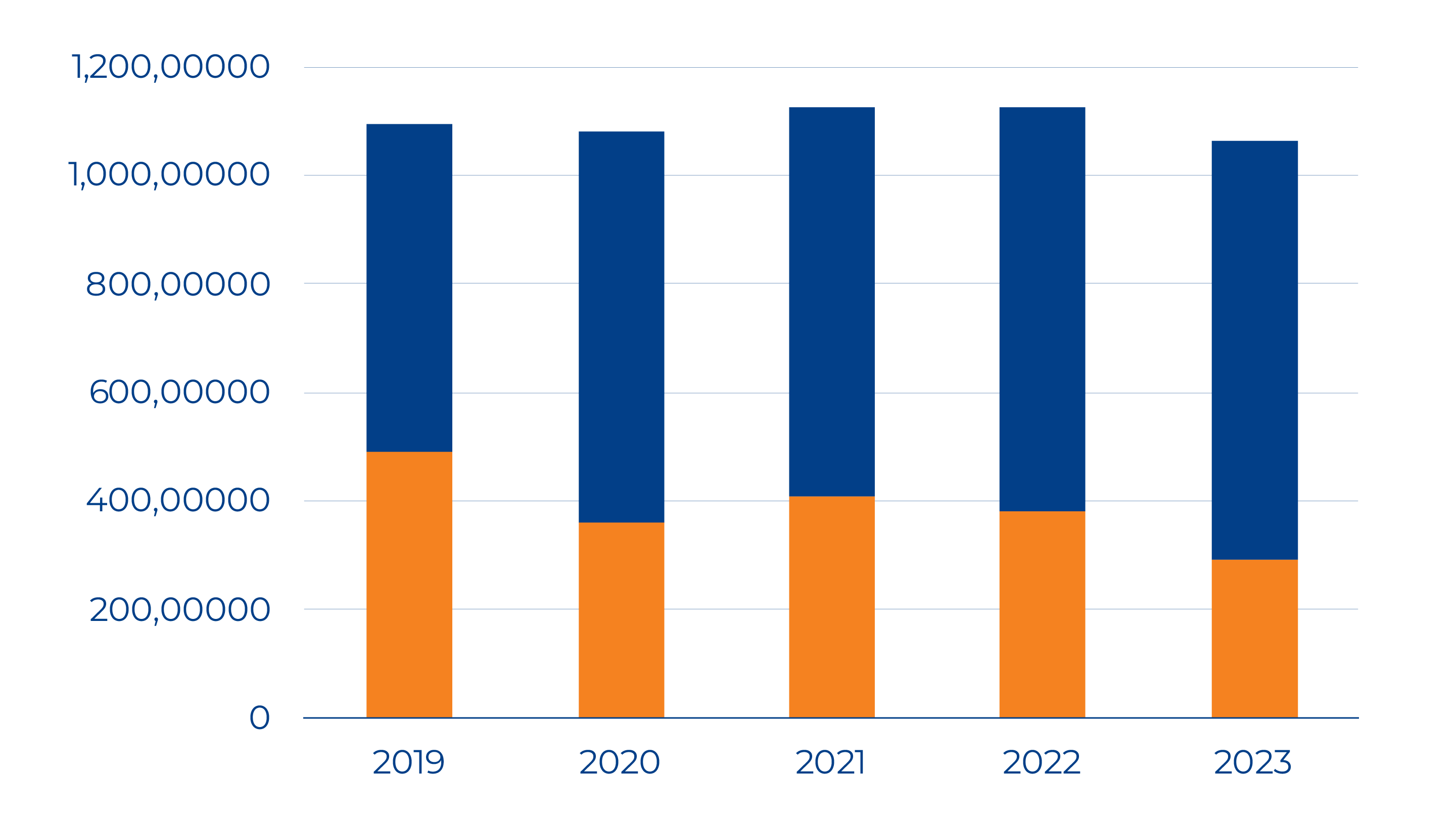

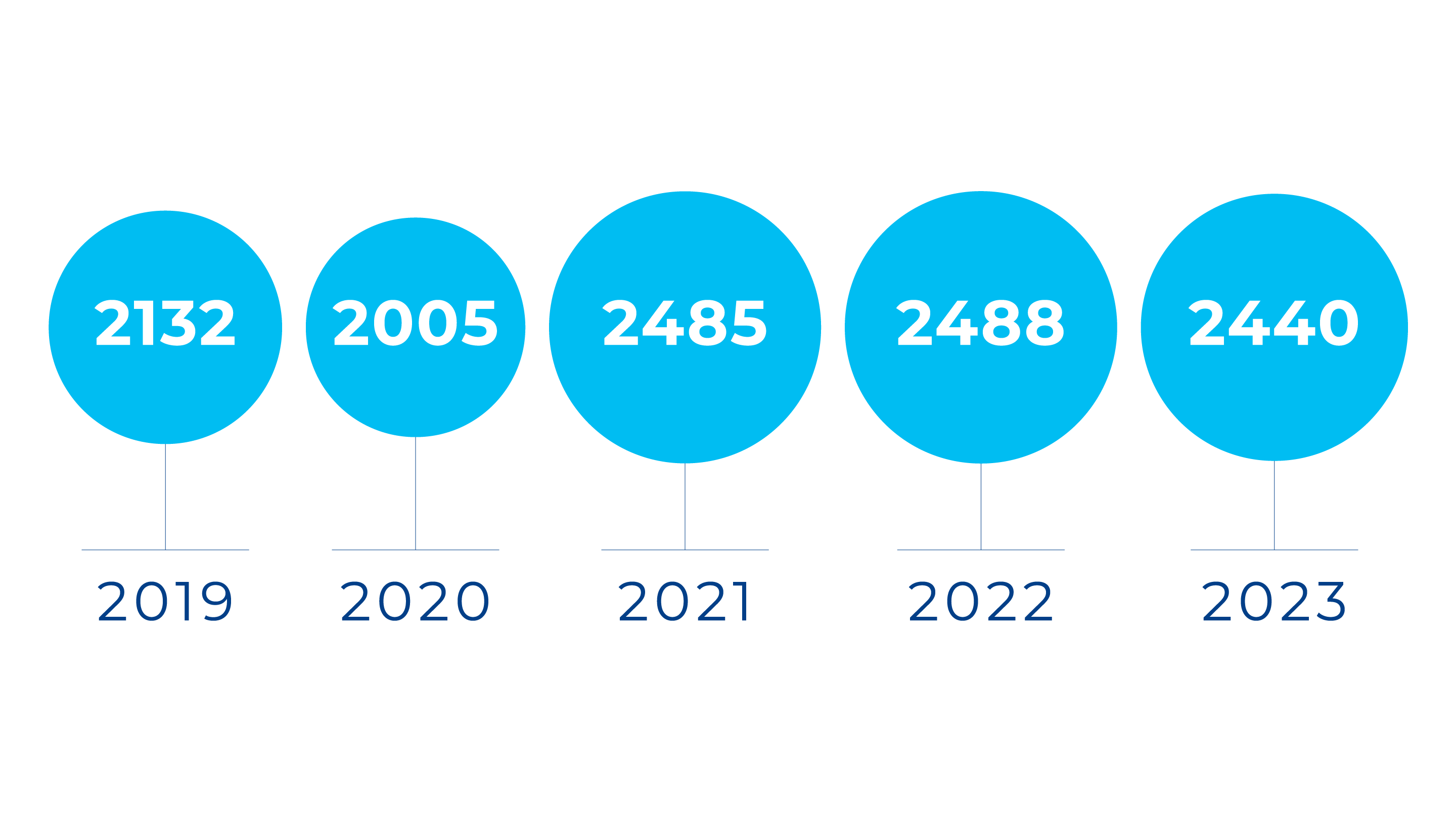

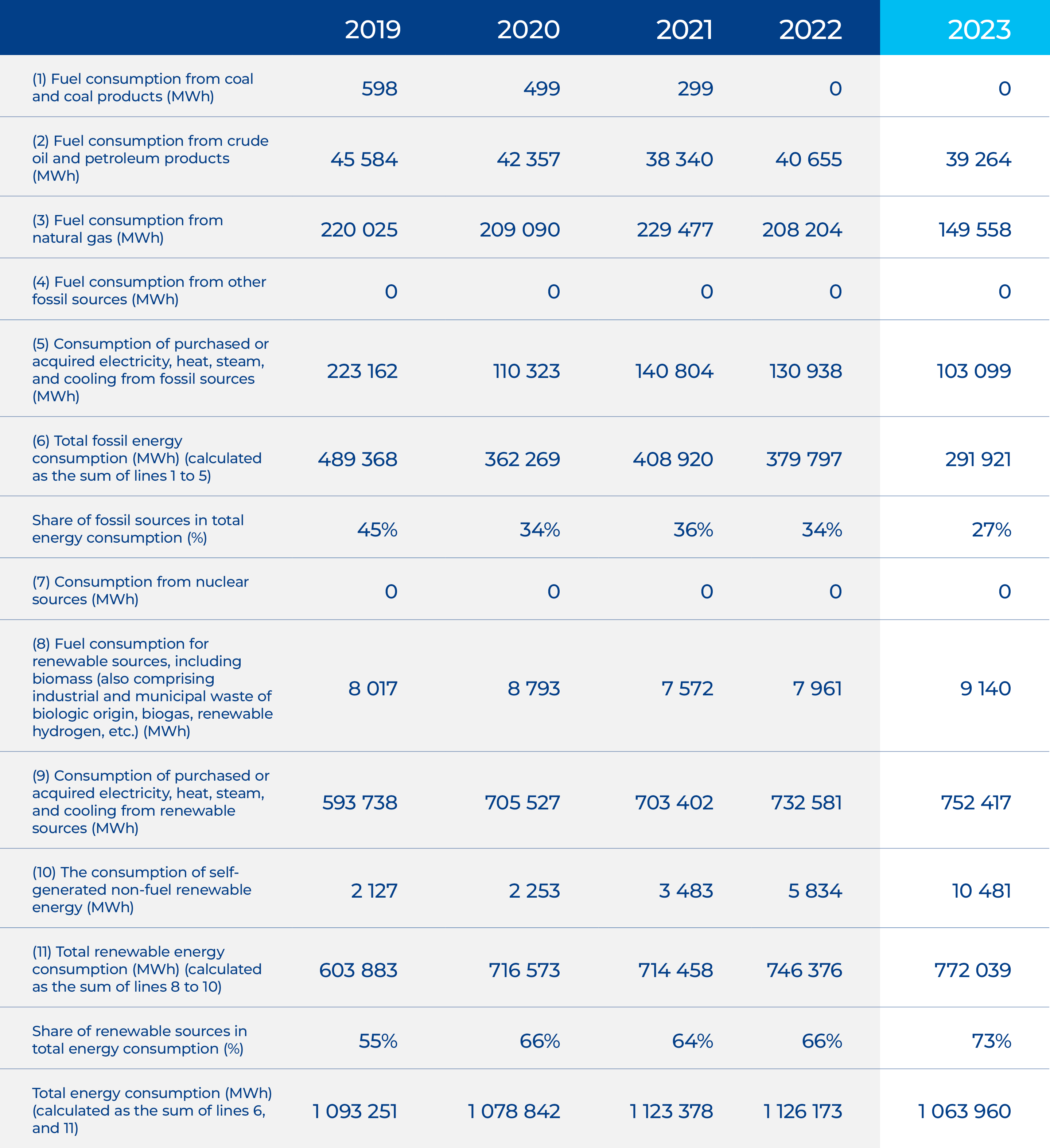

Energy consumption and mix

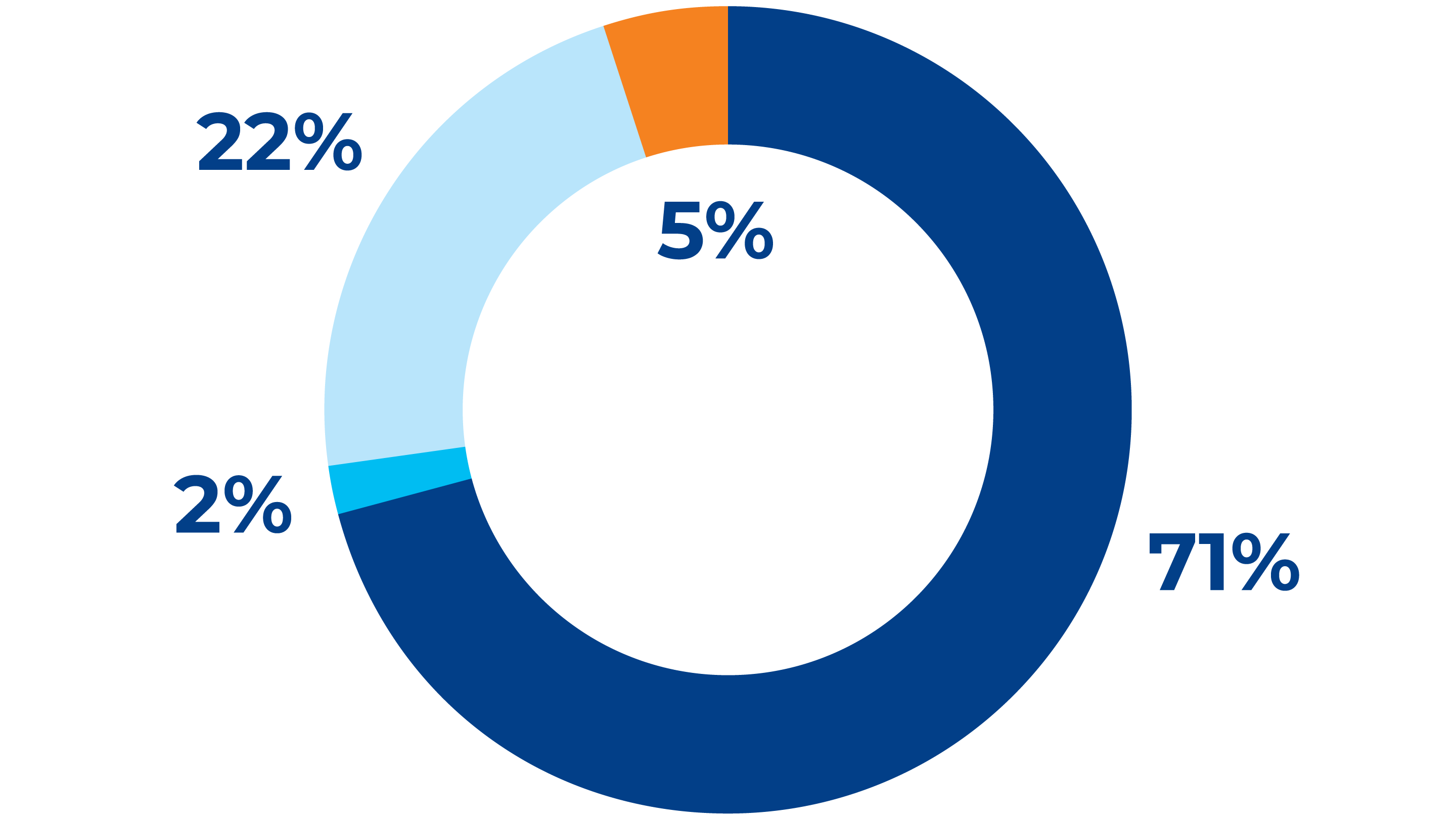

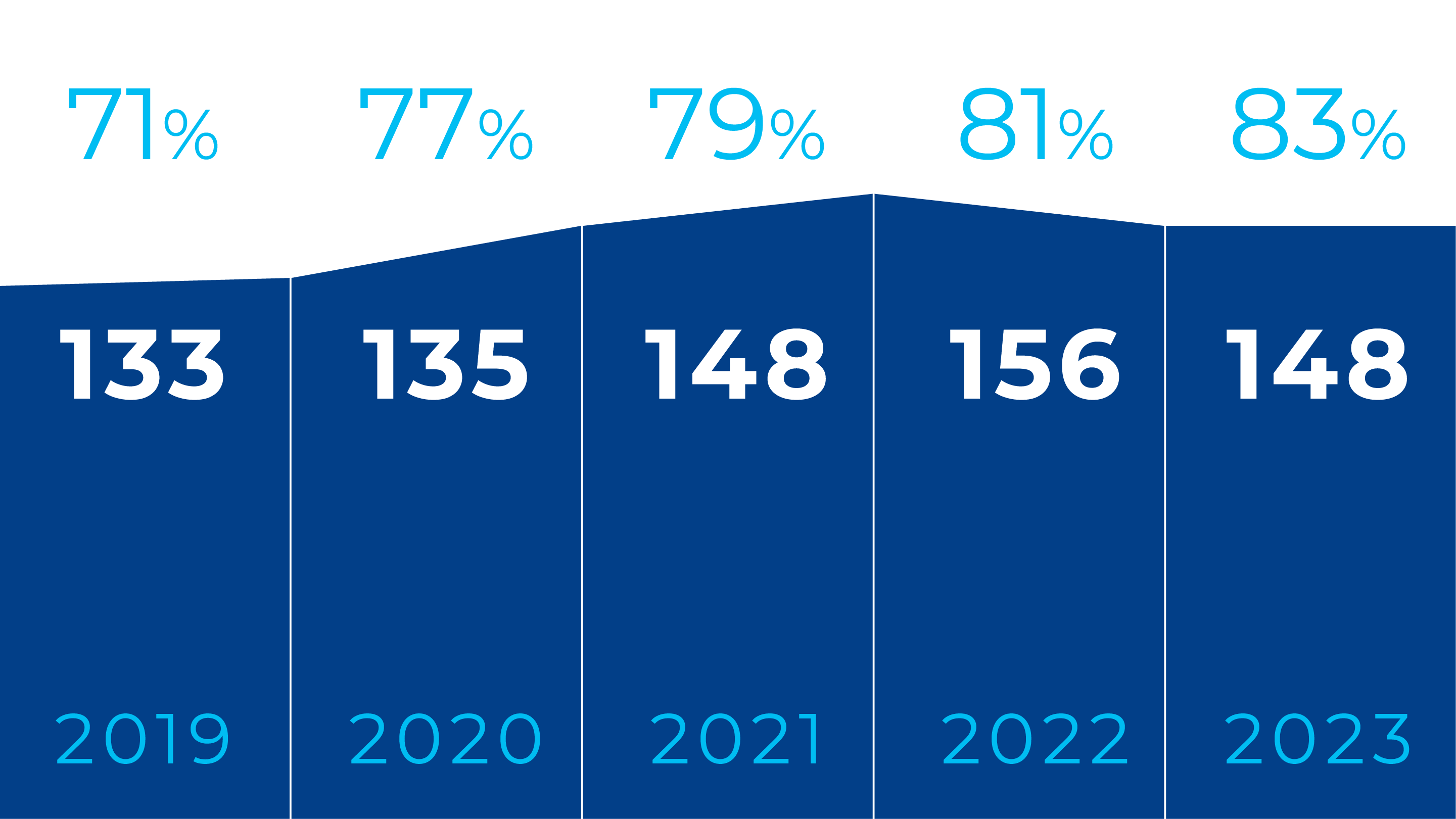

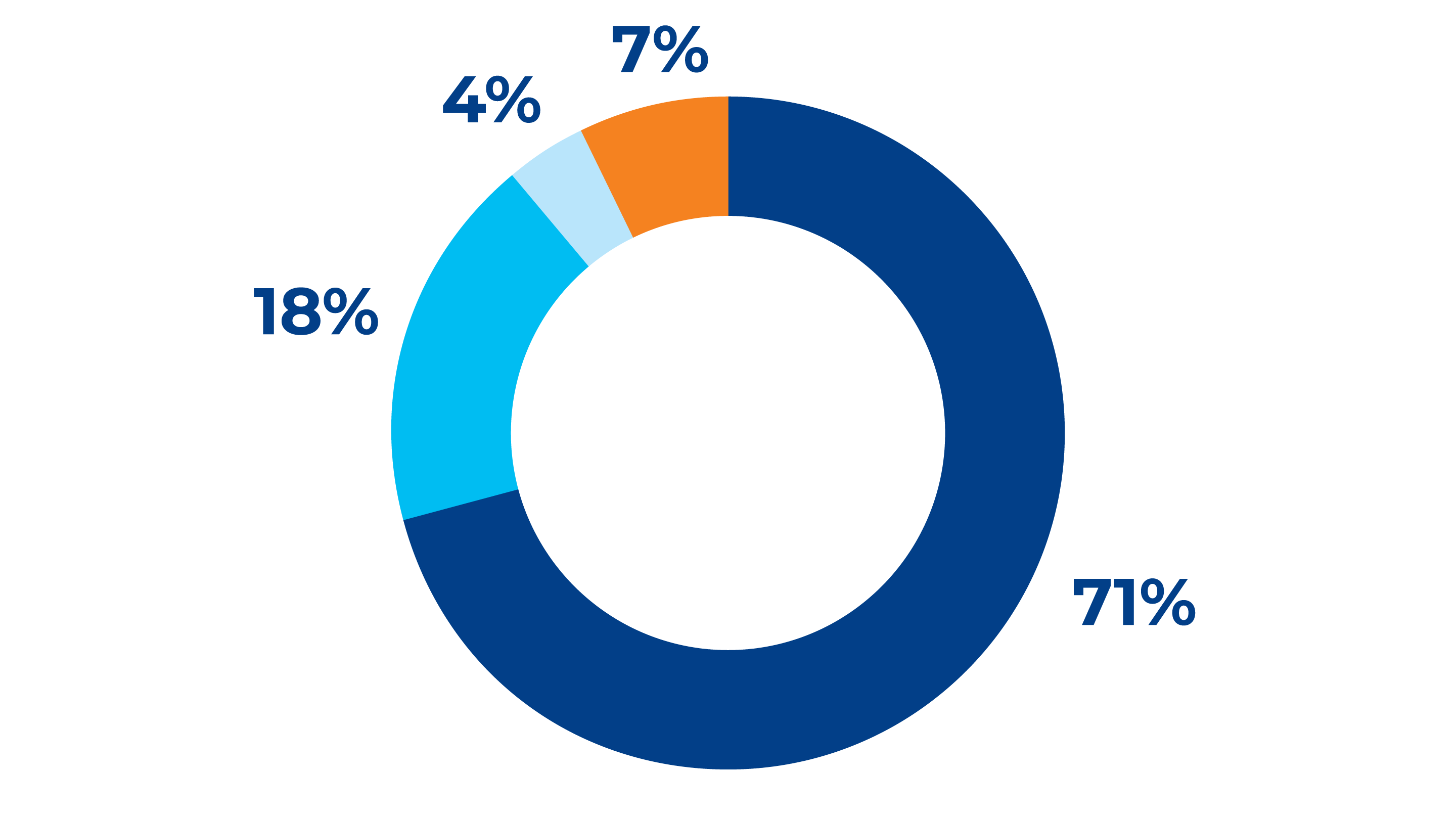

The energy use reported includes purchased and on-site generated electricity, and the use of fossil fuels such as natural gas and district heating (hot water/steam). Electricity is the main source of power for our operations. Fuels are used both for heating and for process-specific purposes such as drying printing inks. Energy use has remained relatively stable, despite increases in production. Our packaging material converting factories are the most energy intensive operations, consuming 71% of the total energy used across our operations in 2023.

Energy consumption and intensity within the organisation

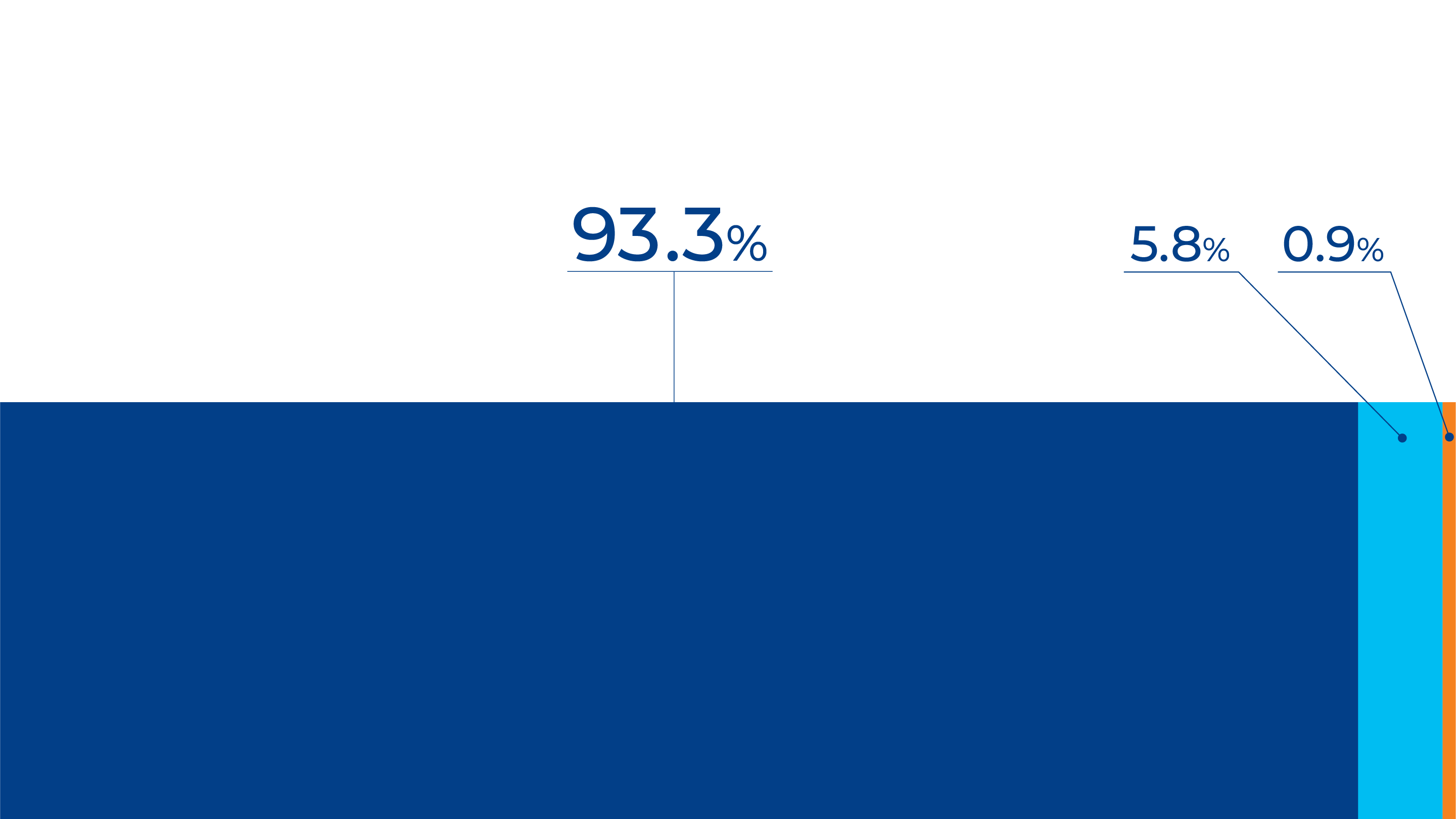

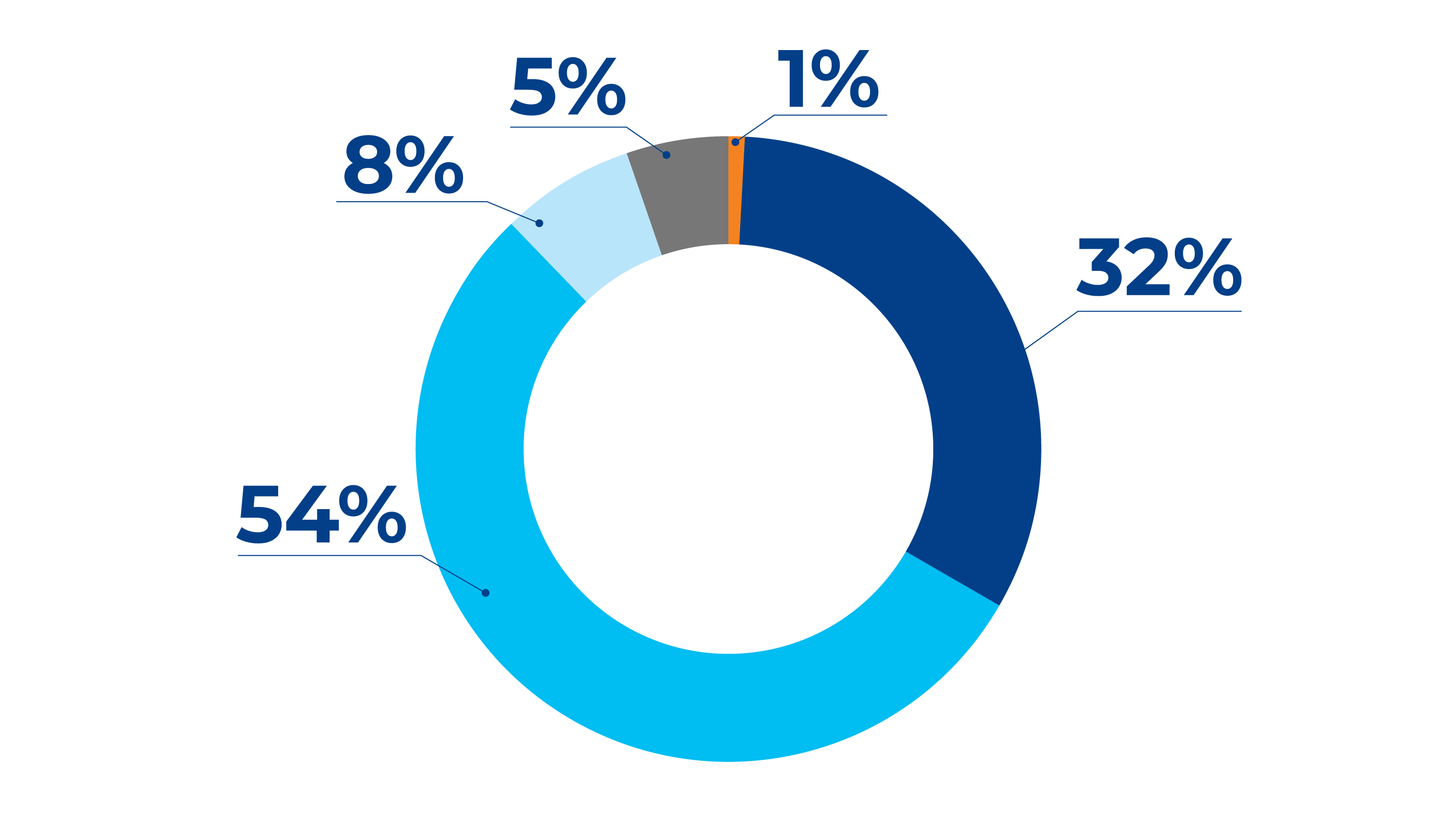

Gross Scope 1, 2, 3 and total GHG emissions

Tetra Pak’s GHG emissions are accounted according to the GHG Protocol principles developed by the World Resource Institute (WRI) and the World Business Council on Sustainable Development (WBCSD). Our Scope 1, 2 and 3 GHG emissions data have been limited assured by a third party since 2013.

Scope 1 includes direct emissions from our own operations, including fuel consumption, the use of refrigerants and solvents. Scope 2 includes indirect emissions related to purchased electricity, heat, steam or cooling. Our Scope 2 was calculated using both location and “market-based” approaches. In the market-based approach supplier-specific emission factors are used where available in line with the GHG Protocol Scope 2 Quality Criteria.

Note: The baseline year for our climate data is 2019. The performance in 2019 is considered to be representative of Tetra Pak operations and the value chain and was the last full year for which an audited GHG inventory was available when our SBTi target was updated in 2020. The GHG emissions are calculated using published generic emission factors. The most recent GWP values provided by the Intergovernmental Panel on Climate Change (IPCC), based on a 100-year time horizon, are used for the inventory. Consolidation approach for emissions: Operational control.

*Categories excluded due to limited impact = 2 (capital goods and services), and 7 (employee commuting). Categories excluded due to not being relevant to Tetra Pak = 8 (upstream leased assets), 14 (franchises), and 15 (investments). **Categories 10 (Processing of sold products) and 13 (downstream leased assets) are included within category 11.

Pollution

Emissions of ODS result from CFCs/HCFCs* leakages. Tetra Pak’s policy is to replace CFCs, halon and all other substances with high ozone depleting potential with alternative substances that have a lower environmental impact. Since implementing this policy our emissions from ozone depleting substances have dropped to marginal levels.

VOC emissions arise mainly from solvents used in printing inks and, to some extent, from printing plate production at our packaging material converting factories. The data represents total VOC emissions to air, after abatement equipment. It includes both process emissions, stack emissions, as well as fugitive emissions. In order to reduce these emissions, we have been installing Regenerative Thermal Oxidizers (RTOs) at many of our sites. Furthermore, we are continuously innovating our processes to reduce the use of organic solvents in our production.

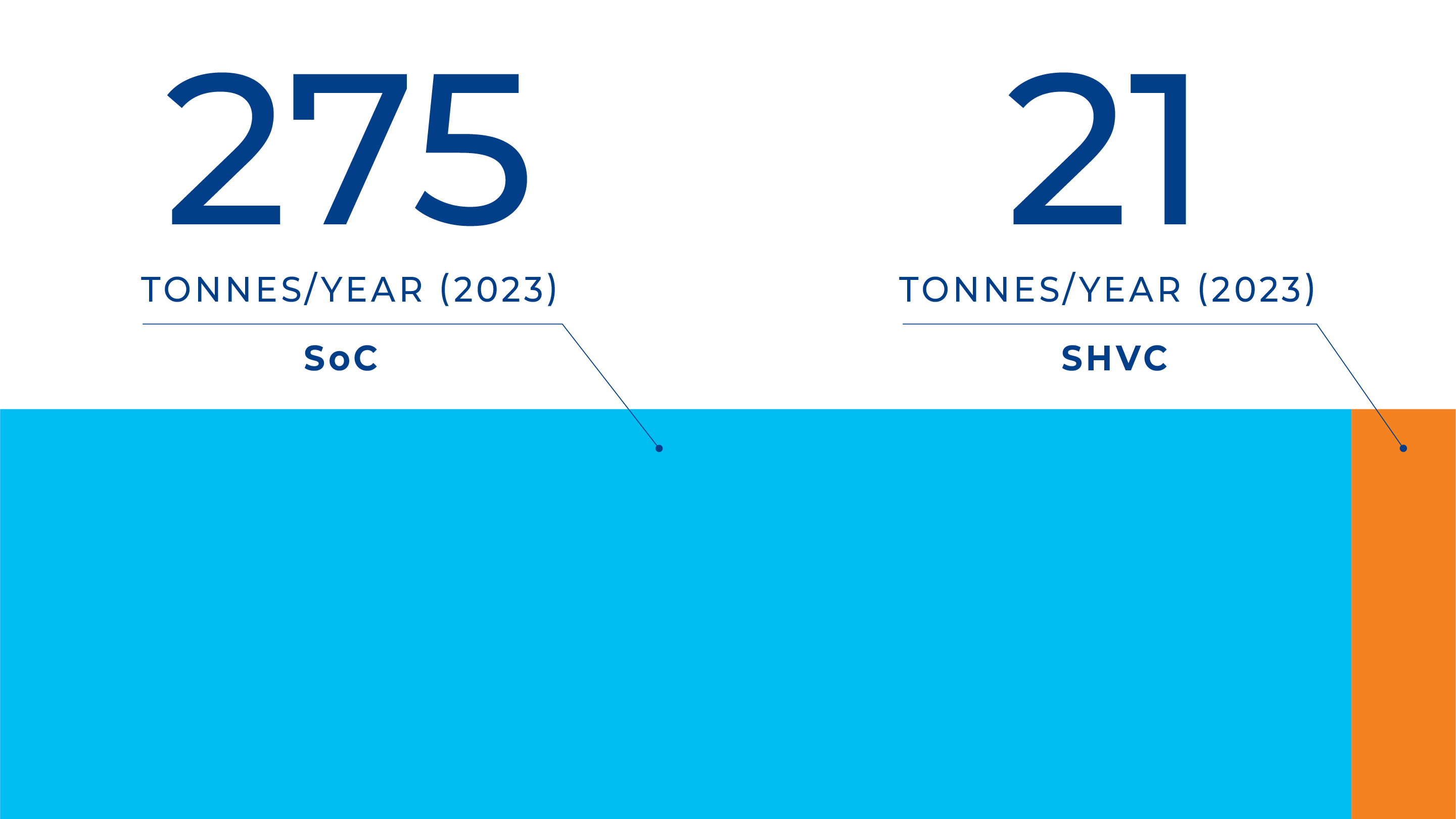

Substances of Concern (SoC) and Substances of Very High Concern (SVHC) are specific chemical constituents to our operations. These substances are utilized within our own processes for a variety of essential purposes, including production, testing and cleaning. Their use is closely monitored to ensure compliance with safety and environmental regulations, reflecting our commitment to responsible management and sustainable practices.

*CFCs: ChloroFluoroCarbons, HCFC: HydroChloroFluoroCarbons

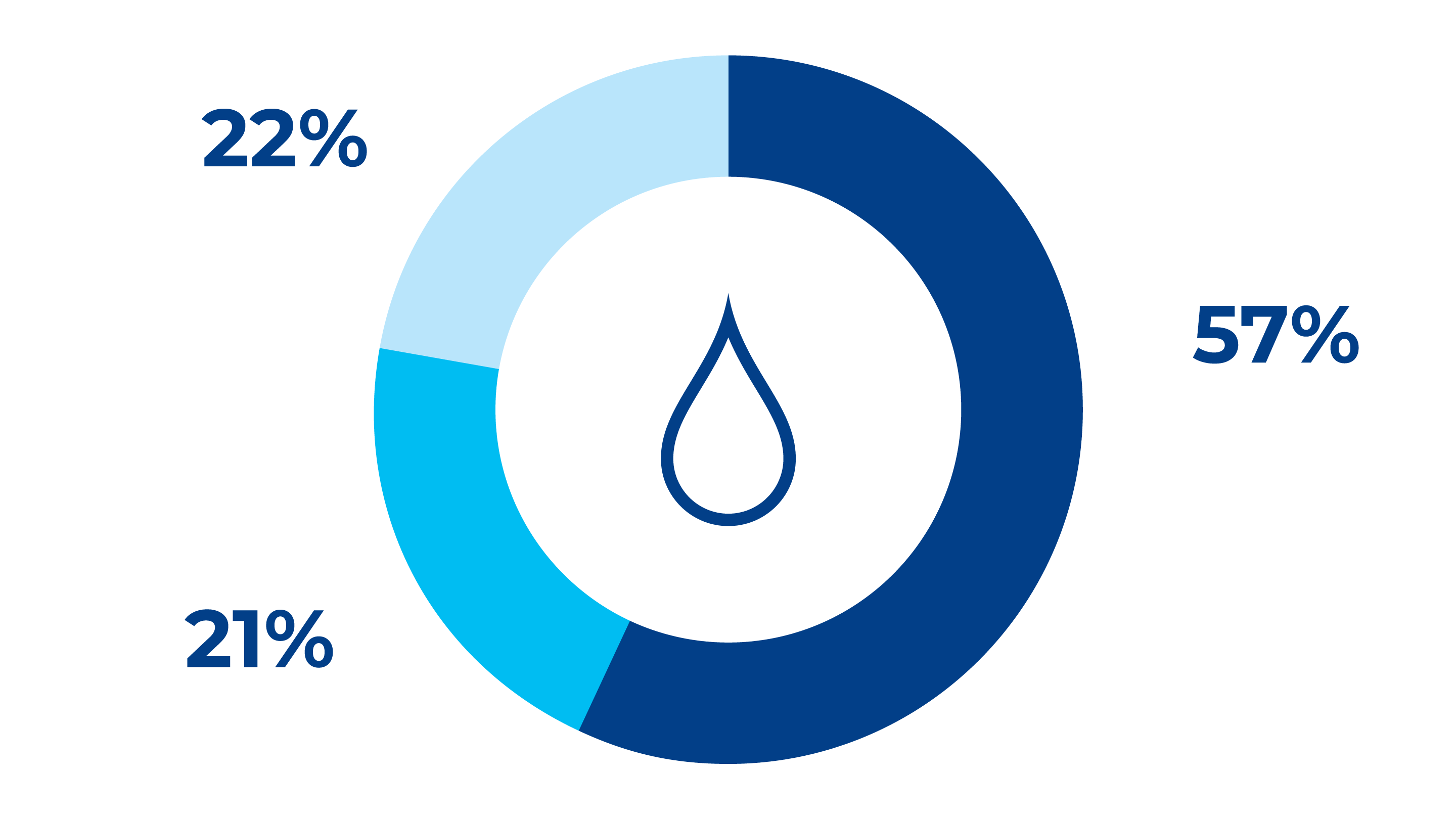

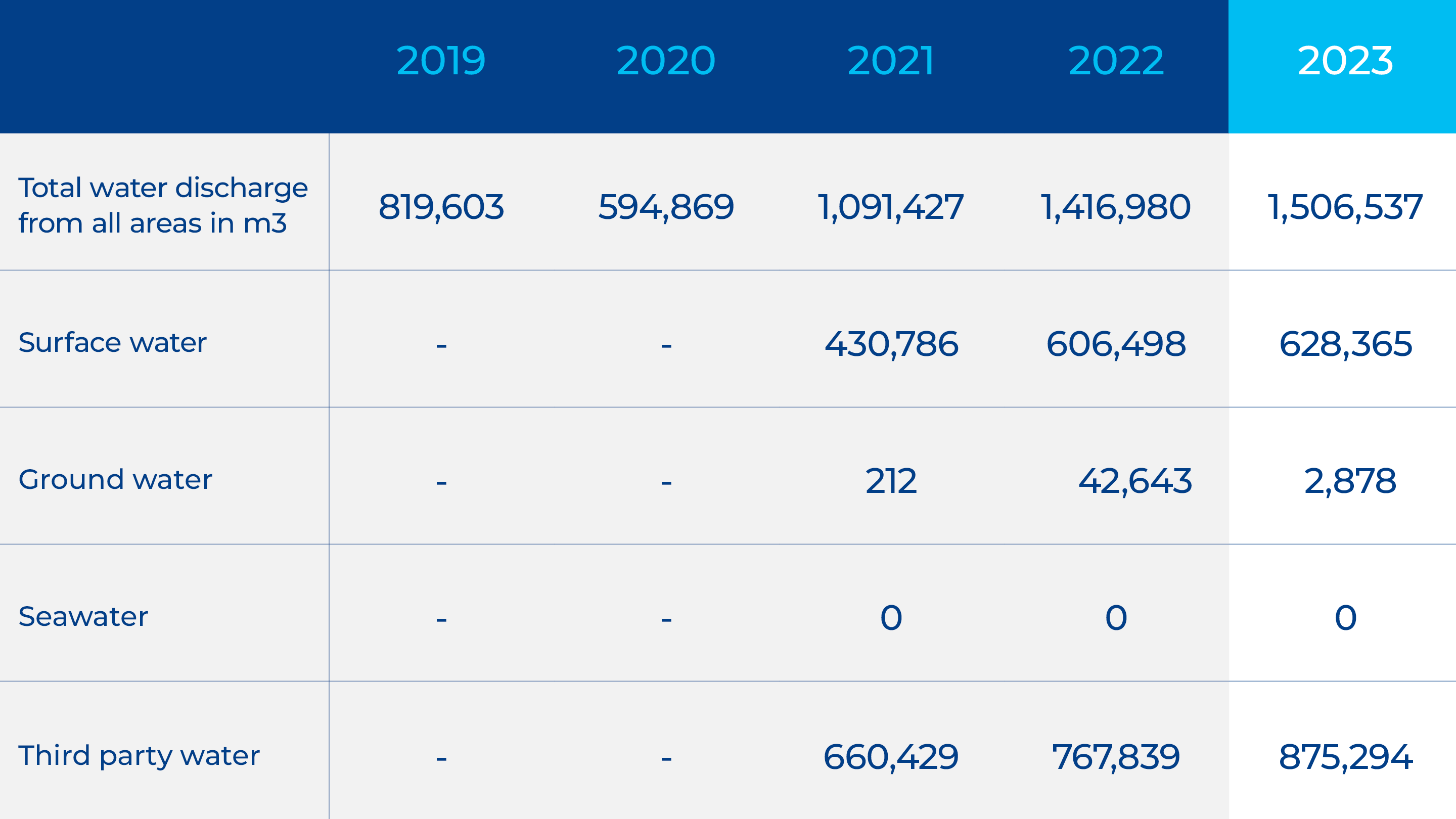

Water management

The data in this section depicts total water consumption, water withdrawal and water discharge across Tetra Pak’s sites. The amount of water we withdraw is modest; nevertheless, we seek to minimize usage withdrawal as far as possible. Our converting factories account for the largest percentage of water use, followed by those operations that assemble machines and equipment. To understand which of our sites are located in water stress areas we have used the WRI Aqueduct Water Risk Atlas tool. It is assumed that all water withdrawn for our sites is fresh water. Tetra Pak’s key focus is on water withdrawal, and it is for that metric that we have set our key water target.

Read more in our Water Data Inventory Report FY2023

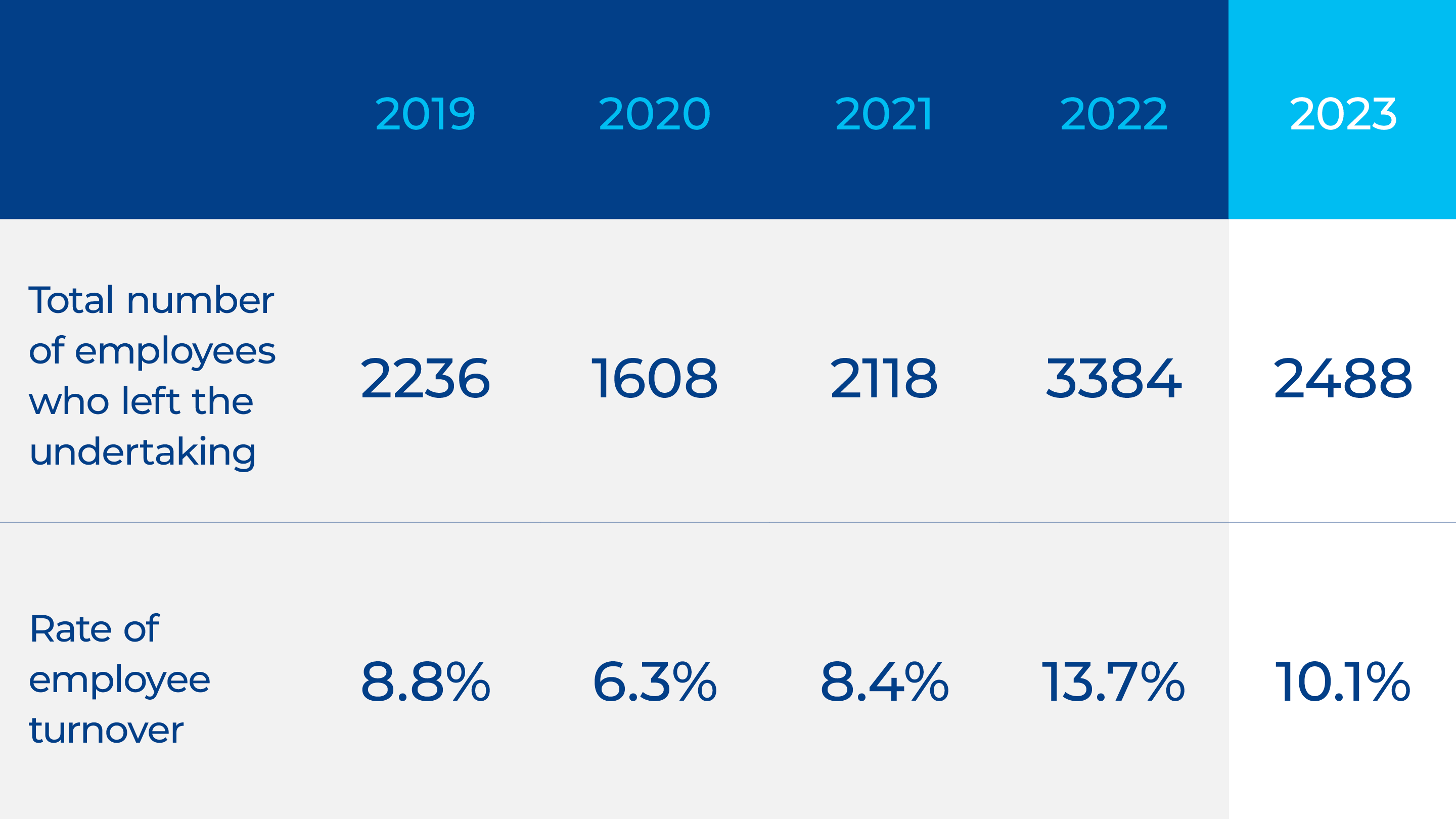

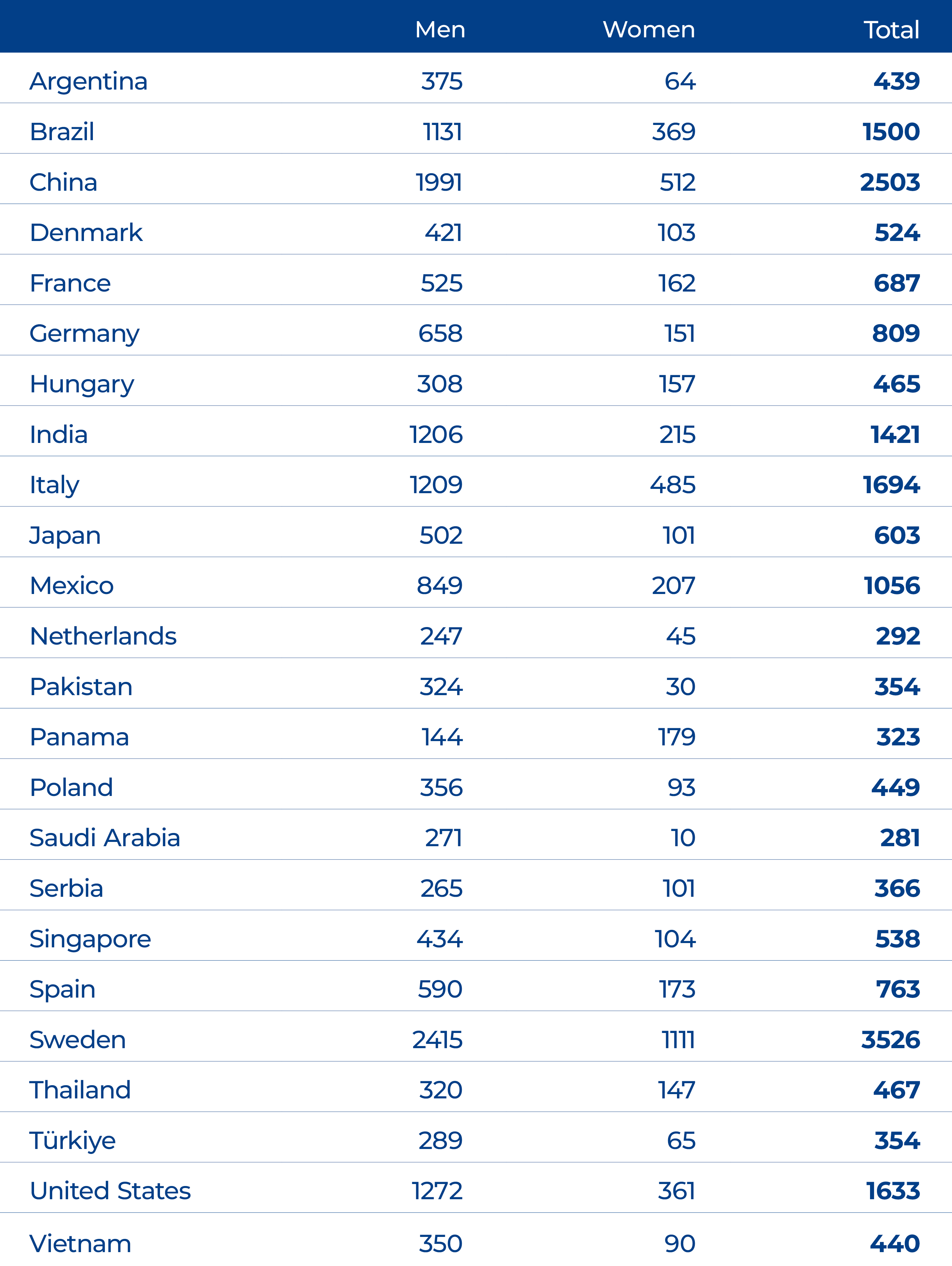

Employees

Characteristics of our employees

Data presented in this section covers the total number of employees at Tetra Pak for the year 2023 by gender, region, working time, and contract type. Here you will also find diversity metrics and health and safety related information.

Number of employees per country* and gender

*This table shows the number of employees per country with 250 employees or more representing at least 10% of Tetra Pak’s total number of employees and the respective breakdown by Gender, as of December 2023. NOTE: Data is end of period Headcount, representing actual number of people employed by Tetra Pak at the end of the year, including if leaving on Dec 31. It includes employees on temporary leave (e.g. maternity, study, sick leave, ‘garden leave’)

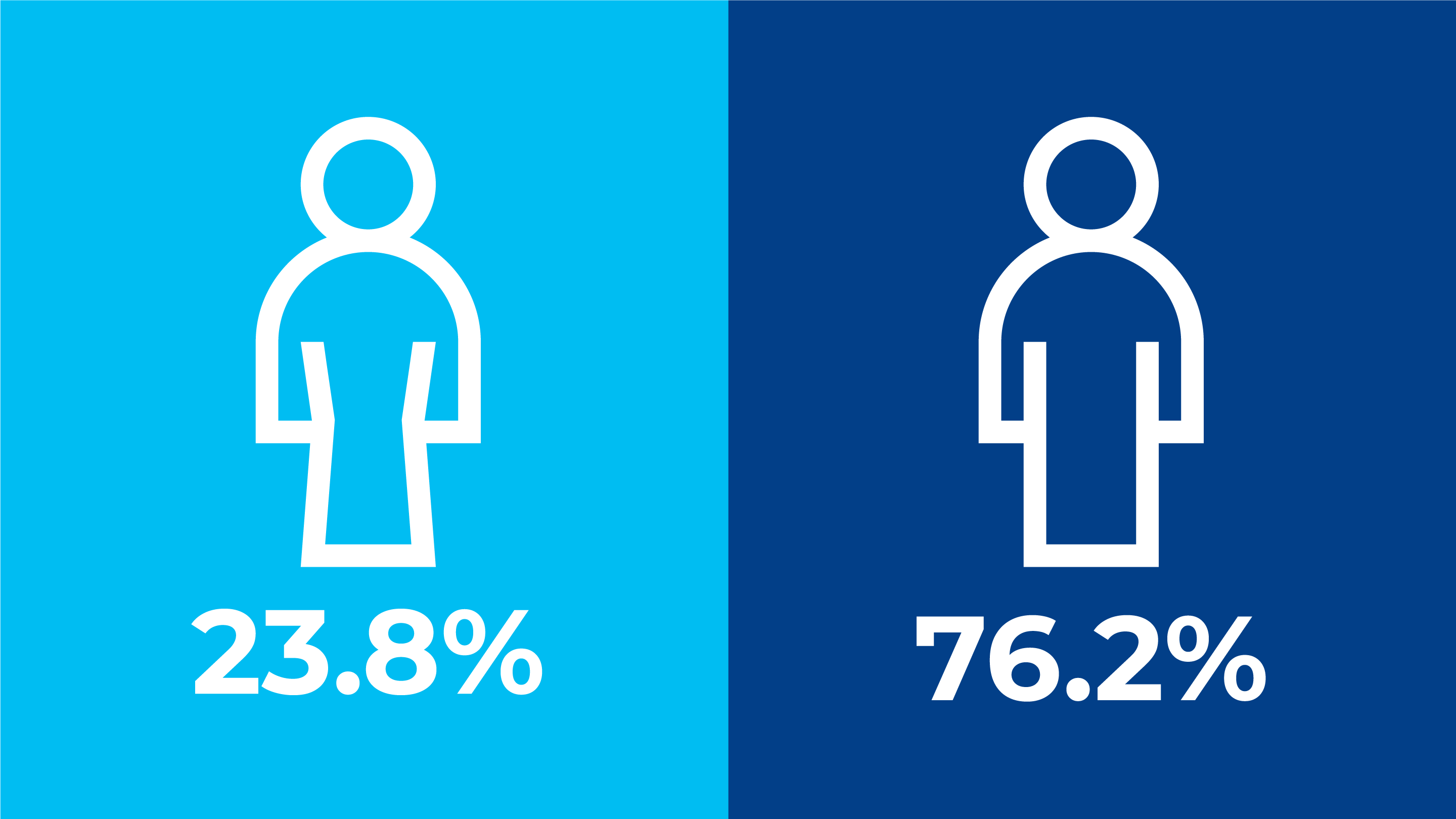

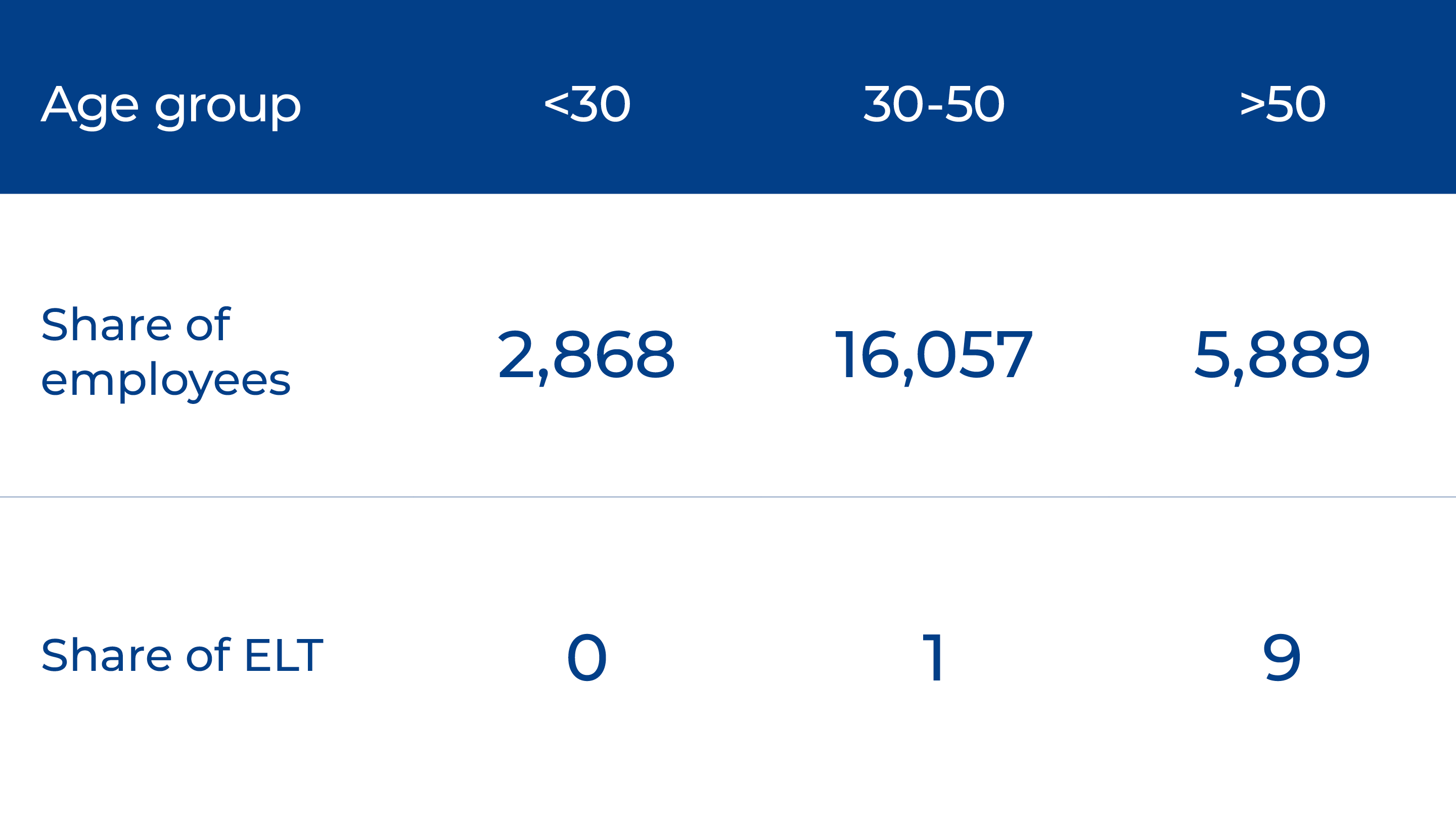

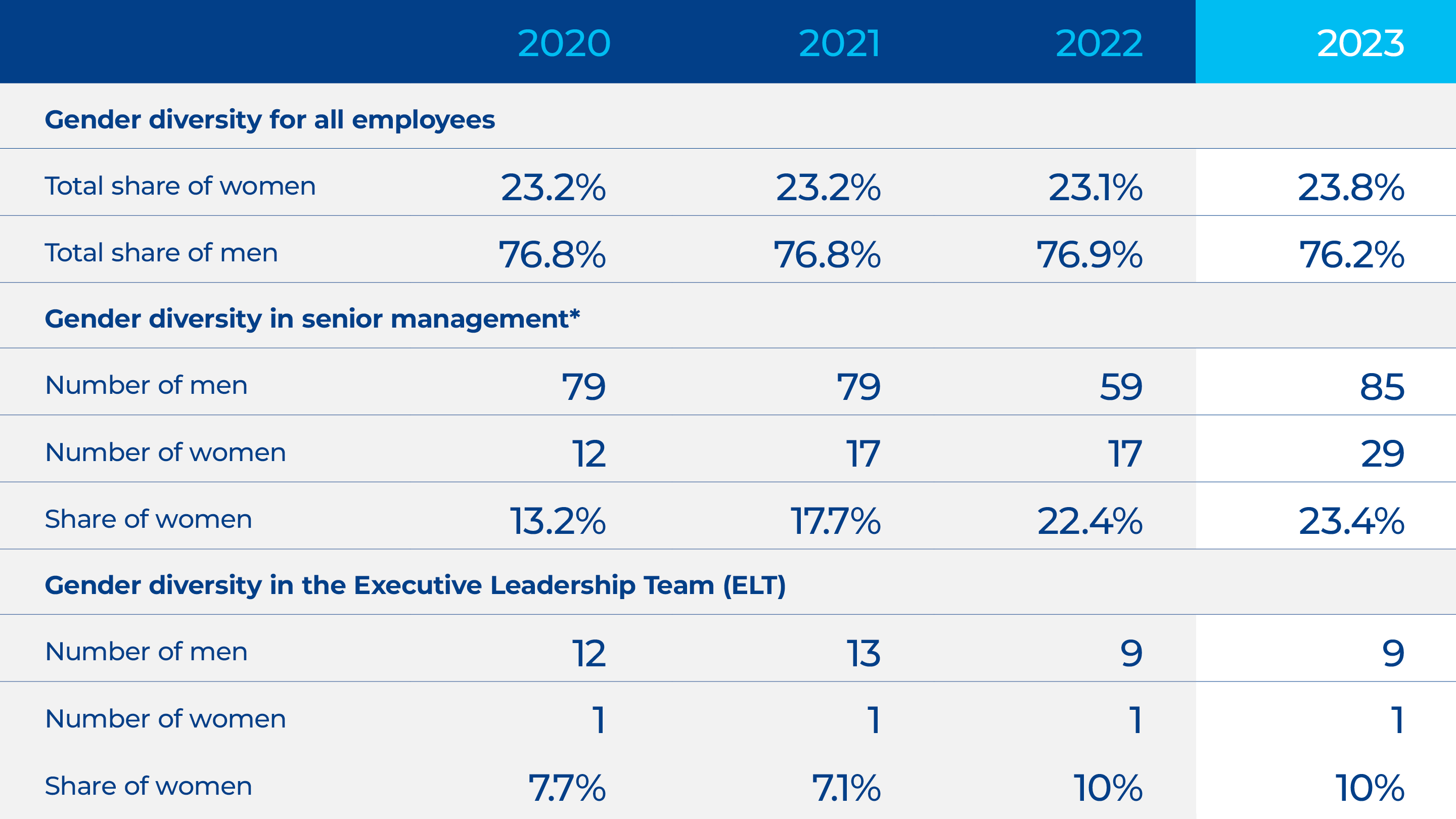

Diversity metrics

Data presented in this section covers the diversity of Tetra Pak's Executive Leadership Team (ELT) and Tetra Pak employees by region, age group and by employee category.

Gender diversity for all employees

*Senior management is defined as Tetra Pak’s employees at Job Level A

Restatements of information

As part of our ongoing review of data and reporting guidance, previous years’ water data has been updated to better reflect an accurate accounting of our water performance. Read more in our Water Data Inventory Report below.