Boost capacity or efficiency – without additional equipment needs

With dairies under greater pressure to increase capacity, the separator has become a limiting factor in many processing lines. For many, this has meant needing to install larger separators – and more of them.

Of course, this is an approach with clear drawbacks. Additional equipment means higher investment costs up front, along with higher operating costs over time due to added consumption of energy and water as well as needs for parts and maintenance. For some existing dairies, installing a bigger or additional separator may not even be possible because of already limited plant space.

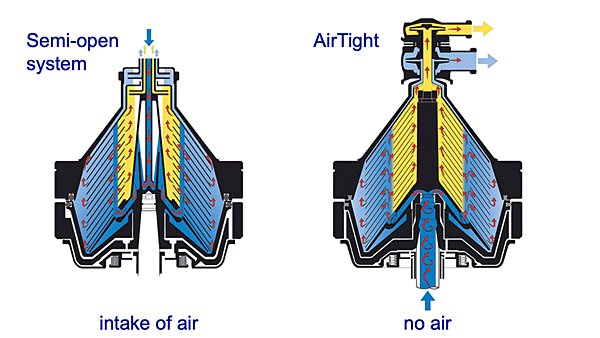

There is therefore demand for separation technologies that can enable higher yield within the same footprint of existing equipment. To understand how this might be possible, it is important to first take a close look at the factors that impact separation capacity and separation efficiency. In this article, we explore the science behind separation surface area in order to explain:

- What limits capacity in separation

- How we can re-think separation design to better respond to today’s needs

- And the new innovations that have already emerged to help solve these challenges

Download ‘The science of separation area’

Is your dairy facing increased demand to improve yield while simultaneously boosting product quality and optimising your process efficiency? Download this article to better understand the science behind separation and how you can get more of what you need out of your equipment.

Please note that this article is in English.