Introduction - pasteurized and ESL milk production

With pasteurized milk and Extended Shelf Life (ESL) milk production, the key considerations are efficiency, safety, flavour, and knowing how raw materials behave when heat-treated and processed in different ways. We can help you develop pasteurized milk processes that maintain the natural taste and characteristics of your product, while ensuring consumer food safety and meeting legal requirements, thanks to our unrivalled expertise in chilled dairy processing and the most efficient food production equipment on the market.

Processing lines for pasteurized and ESL milk

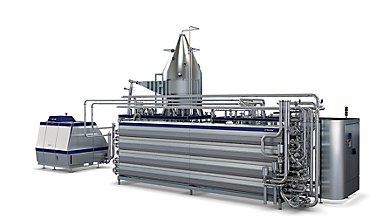

Best-practice line for pasteurized milk

For high volume milk production, this future-proofed line has an extremely efficient and reliable pasteurizer at its heart. The line is designed to maximize food safety, from the materials used to build it to the traceability software in the automation system. With thousands of installations in dairies around the world, this technology is well-proven.

Explore the Best-practice lines for chilled milk productsBest-practice ESL-line: pasteurization + bactofugation

The pasteurizer in this line has an integrated centrifugal separator and can also include a spore removal separator (commonly referred to as bactofugation) to reduce microbiological load. This increases the products' shelf life while maintaining the flavour of pasteurized milk. Every line is customized to match the customer's preferences and prerequisites.

Explore the Best-practice lines for chilled milk productsBest-practice ESL-line: high heat treatment

The pasteurization temperature of this line is higher than that of a pasteurized milk line, but lower than that of a UHT milk line. It targets organisms (bacillus cereus) to increase shelf life and can give producers the flexibility to run both UHT and ESL products on the same line.

Explore the Best-practice lines for chilled milk productsInsights - Sign up for the ESL white paper