Oat drink processing

Consumer love for oat beverages is snowballing, propelling oats past other plant-based raw materials to become the most important ingredient in many large markets, and the fastest growing plant-based drink. Seize new plant-based processing opportunities in oat processing thanks to our complete solutions, designed with the knowledge and expertise gained from being a pioneer in oat drink processing and packaging.

The surprising versatility of oat drink processing

Oat drink processing lets you target specific consumers with tailored product profiles – and produce any product you could formulate with ordinary dairy milk:

- Clean-label – just water, oats, oil, salt

- Flavoured – chocolate, vanilla, strawberry, etc

- Functional – with nutrients such as calcium and vitamins or stabilisers for specific properties

- Blended – with milk or fruit juice

- Beyond beverage – oat extract for yoghurt, cooking cream, cheese, ice cream and more

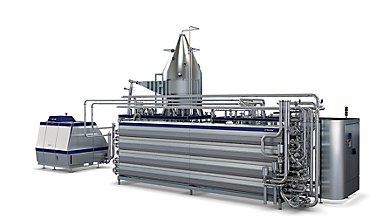

Processing lines for oat beverages

Best-practice line for oat beverages – based on oat flour

Best-practice line for oat beverages – based on oat flakes or grains

Best-practice line for oat beverages – based on oat concentrate

Let's shape the future of plant-based beverages

What could the future have in store for the plant-based beverage market? And how can you make strategic plans for the years to come? Plant-based foresight is a strategic, data-driven methodology that looks beyond consumer trends to explore what the future of plant-based beverages could be.