Membrane types and applications

The heart in any membrane filtration process is the membrane itself, and choosing the best membrane for a given process is often a complex task. Membrane type, plant design and processing parameters should be carefully matched to meet the desired performance and cost-efficiency of the overall process.

Tetra Pak is one of the world's largest providers of membranes for dairy applications, and we offer supply and replacement of membranes and all types of spare parts for membrane filtration systems.

Spore removal with membrane filtration

Combatting spores

Many methods are being used to kill and remove spores from milk and whey. Spores are particularly difficult to get rid of, being robust and some resistant to pasteurization, UV and gamma radiation, freezing, dessication, and treatment with chemical compounds. However, these approaches downgrade the quality of the product considerably, consume energy, and affect the environment negatively.

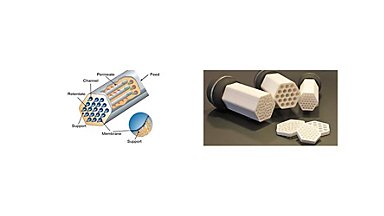

Ceramic microfiltration

An effective and environmentally friendly way to reduce the number of bacteria and spores drastically is the use of ceramic microfiltration, which ensures up to log 6 reduction. The bacteria and spores are removed from the product stream, along with bacterial enzymes and somatic cells.