Oat drink processing

Consumer love for oat beverages is snowballing, propelling oats past other plant-based raw materials to become the most important ingredient in many large markets, and the fastest growing plant-based drink. Seize new plant-based processing opportunities in oat processing thanks to our complete solutions, designed with the knowledge and expertise gained from being a pioneer in oat drink processing and packaging.

The surprising versatility of oat drink processing

Oat drink processing lets you target specific consumers with tailored product profiles – and produce any product you could formulate with ordinary dairy milk:

- Clean-label – just water, oats, oil, salt

- Flavoured – chocolate, vanilla, strawberry, etc

- Functional – with nutrients such as calcium and vitamins or stabilisers for specific properties

- Blended – with milk or fruit juice

- Beyond beverage – oat extract for yoghurt, cooking cream, cheese, ice cream and more

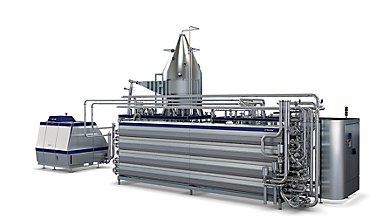

Processing lines for oat beverages

Best-practice line for oat beverages based on oat flour

This line combines high efficiency with low environmental impact. It lets you achieve desired product quality and reduce your consumption of energy, water and raw materials. The line begins with powerful high shear mixing. Next comes a highly controlled enzyme treatment and deactivation process. Fibre separation, powerful high shear mixing and homogenisation optimise beverage properties. Heat treatment ensures food safety.

Explore Best-practice lines for oatBest-practice line for oat beverages based on oat flakes or grains

This line includes grinding and a highly controlled enzyme treatment and deactivation process to achieve the desired product flavour. Fibre separation, powerful high shear mixing and homogenisation optimise beverage properties. Heat treatment ensures food safety.

Explore Best-practice lines for oatBest-practice line for oat beverages based on oat concentrate

This line begins with powerful high shear mixing to give you full formulation control, allowing you to fine tune products to match consumers’ texture and taste preferences. Choose between two different heat treatment methods to ensure food safety.

Explore Best-practice lines for oat