Welcome to a whole new world of soya

It’s time to reinvent soya beverages. Meet the emerging trends and take advantage of key consumer preferences to develop your soy-based portfolio. For instance, the health and wellness trend creates opportunities for soy products with functional health benefits, or consider embracing the clean label trend with 'no artificial ingredients' and 'free from' claims. Appeal to the growing number of young consumers adopting plant-based diets for environmental or ethical reasons. Soy, as one of the few plant-based sources containing essential nutrients, can play a starring role in the diets of many vegetarians and vegans.

Whole bean soya, with its potential for high protein and fiber, offers producers and consumers alike a new alternative to traditional soya products. We provide comprehensive support, from formulation and testing to packaging and commercialization, to help you succeed in this innovative venture.

Expertise in whole soya solutions

As soya beverage pioneers, we have the expertise and solutions to help you make the most of opportunities in this new category, from formulation and testing to ensuring a richer flavour and creamier mouthfeel.

Expertise in whole soya solutions

As soya beverage pioneers, we have the expertise and solutions to help you make the most of opportunities in this new category, from formulation and testing to ensuring a richer flavour and creamier mouthfeel.

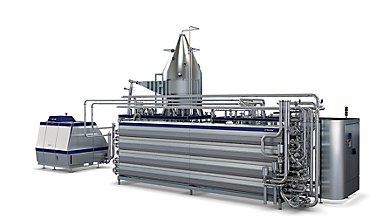

Processing lines for soya products

Whole bean soya beverages

A complete proven technical solution for whole bean soya beverages, the line includes whole soya extraction (grinding, trypsin inhibitor deactivation and fine grinding) and different process configurations (grinding, enzyme deactivation, fine grinding or grinding, enzyme deactivation, fibre separation, and okara fine grinding) to allow either complete or partial utilisation of okara. Post-extraction treatments create multiple different product formulations and optimises their properties.

PD leaflet best-practice line for whole bean soya beveragesTraditional extracted soya beverages

This line is designed for the production of soya beverages extracted from soya beans and includes extraction (grinding, trypsin inhibitor deactivation, and fibre separation) and processing, while the application of different process configurations (grinding, fibre separation, enzyme deactivation or grinding, enzyme deactivation, fibre separation) and parameters (beany to low beany) allows flexibility to match your consumers’ requirements. Post-extraction treatment in terms of powerful high-shear mixing helps create multiple product formulations from the soya base.

PD leaflet best-practice line for traditional extracted soya beveragesSoya extraction line

Starting from whole or dehulled beans, this extraction line integrates grinding, fibre separation, and enzyme deactivation, ensuring a high protein yield and full control over product flavour – from beany to non-beany. After extraction, the base is homogenized for texture and heat treated for safety.

Read more about soya extractionSoya powder line

Starting from powders, this line offers excellent control over essential product properties like taste and texture. Intensive, high shear mixing disperses the powder, then efficiently dissolves and emulsifies the ingredients. Choose between two different heat treatment methods to ensure end product safety.

Read more about soya powder lineProcessing equipment for soya products

What is quality in whole bean soya beverage?

Many have tried and failed. So, what’s the secret to achieving the right flavour, mouthfeel, viscosity, stability and nutritional value when producing whole soya bean beverages? Our new white paper explains the processing factors required to get all these elements just right.

What is quality in whole bean soya beverage?

Many have tried and failed. So, what’s the secret to achieving the right flavour, mouthfeel, viscosity, stability and nutritional value when producing whole soya bean beverages? Our new white paper explains the processing factors required to get all these elements just right.