Product detail

| Product code | Alfa Laval Filter/ Strainer |

| Applications | Filter for use in dairies, breweries and other food industries as well as in the pharmaceutical and other light chemical industries |

Alfa Laval LKIF In-Line Filter

LKIF is a sanitary in-line filter for use in dairies, breweries and other food industries as well as in the pharmaceutical and other light chemical industries.

LKIF is designed for filtering particles from the products, e.g. for protection of pumps and other sensitive equipment.

Working principle

- The filter can easily be removed for cleaning without any interference with the process plant.

- It is recommended to install the filter so that the inlet flow is as shown in fig.1. The particles will then be accumulated at the inside of the filter which facilitates the cleaning process.

- The inlet flow can, however, be in the other direction, if required.

Alfa Laval LKSF Slot Strainer

LKSF has a wide range of applications within process filtering, especially where strainers of hygienic design are required.

Working principle Type LKSF-BL.

- The product enters at A. Impurities are stopped by the filter element.

- When the filter is full of particles, it can be cleaned by removing the clamp and pulling out the filter element. It is also possible to reverse the flow and flush out the impurities (back flush).

Working principle Type LKSF-CL

- The product enters the filter at A. Most of the impurities will collect at the bottom and can be emptied via a valve, during operation.

- Emptying can also be automatic by means of two remote controlled valves at B.

- The upper valve is open during operation and the lower is closed. The impurities will collect between the two valves. Closing the upper valve and opening the lower one will empty the impurities with a minimum of product loss. The filter can be cleaned as LKSF-BL. The degree of filtering can be altered by changing filter element. Strainer type LKSF-CL must always be installed vertically. The degree of filtering may be changed immediately by changing elements.

Alfa Laval LKVF Coarse Strainer

LKVF has a wide range of applications where removal of particles from a flow is required, eg. for protection of a pump or other sensible equipment.

As options other perforations and mesh sizes are available as well as monel screens. The strainer cap can be drilled and tapped for blowdown and drain valves if required.

Technical specifications

| Product code | Alfa Laval Filter/ Strainer |

| Applications | Filter for use in dairies, breweries and other food industries as well as in the pharmaceutical and other light chemical industries. |

Alfa Laval LKIF In-Line Filter

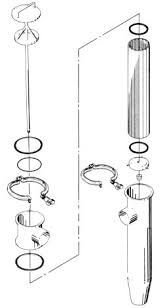

The filter consists of a filter element, clamp or union parts and seal rings.

Max. product pressure: 1000 kPa (10 bar).

Min. product pressure: Full vacuum.

Temperature range: -10°C to 140°C (EPDM).

All wetted parts: Acid-resistant steel AISI 316.

Other steel parts: Stainless steel AISI 304.

Seals: EPDM rubber.

Other seals: Nitrile (NBR) and PTFE, if clamps.

Finish: Semi bright.

Alfa Laval LKSF Slot Strainer

| Max. Working Pressure (20°C) | 1000 kPa (10 bar) |

| Temperature Range | -100°C to +140°C (EPDM) |

| Strainer Area | 1100 cm² |

| Max. Δp in Flow Direction | 1000 kPa (10 bar) |

| Capacity | 10-120 m³/h (water) at Δp = 1 bar |

| Materials | |

| Product-Wetted Steel Parts | AISI 316 |

| Other Steel Parts | AISI 304 |

| Seals | EPDM rubber |

| Surface Finish | Semi bright |

Standard Design: Both strainer types consist of a housing in three parts, LKSF-BL has housing in two parts (101.6 mm)(4”) in which the strainer element is placed. The housing is assembled by means of clamps, (the upper clamp ring has a wing nut for manual operation) to allow for quick dismantling for the cleaning. The strainer element is fitted centrally in the housing and has direct access to the end cover of same where a welded on handle facilitates dismantling when cleaning is required.

Alfa Laval LKVF Coarse Strainer

| Max. Product Pressure (A=inlet) | 1000 kPa (10 bar) |

| Max. Product Pressure (B=inlet) | 700 kPa (7 bar) |

| Min. Product Pressure | Full vacuum |

| Temperature Range | -10°C to 140°C (EPDM) |

| Strainer Area | |

| 25-38-51mm | 430 cm² |

| 63.5-76.1mm | 840 cm² |

| Product-Wetted Steel Parts | Acid-resistant steel AISI 316 |

| Other Steel Parts | Stainless steel AISI 304 |

| Seals | EPDM rubber |

| Surface Finish | Semi bright |

| Material Grades | Seal of nitrile (NBR) or PTFE |