Product detail

| Product code | Reducing valves SRV2 - Spirax Sarco |

| Applications | Steam Pressure Reducing Valve regulates the steam pressure downstream from the valve to a pre‑adjusted set point value. |

Direct acting - Low capacity

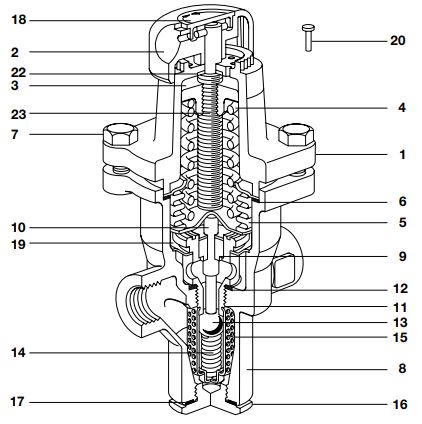

The downstream pressure signal moves a set of bellows against an adjustable spring. Valve movement is proportional to downstream pressure. The greater the flow, the larger the offset.

For clean steam applications

Features & Benefits:

- Extremely robust

- Easy to adjust

- Easy to maintain chamber is closed. The product can then flow from one line to the other.

Steam Reducing Station

Many industrial plants produce high-pressure steam for process work. In many of these plants, there is excess steam capacity available that can be utilized for other purposes, such as space heating, water heating, etc. Process steam is often generated at a higher pressure than can be used for the other purposes. Whatever the needs for lower pressure steam, a pressure reducing station will be required.

A pressure reducing station is more than just a reducing valve fed off a steam main. A properly designed and installed pressure reducing station takes into consideration velocity, good piping practices, and safety.

Technical specifications

| Product code | Reducing valves SRV2 - Spirax Sarco |

| Applications | Steam Pressure Reducing Valve regulates the steam pressure downstream from the valve to a pre‑adjusted set point value. |

Direct acting - Low capacity

Standards This product fully complies with the requirements of the European Pressure Equipment Directive 97 / 23 / EC

Certification This product is available with certification to EN 10204 3.1. Note: All certification / inspection requirements must be stated at the time of order placement.