UHT milk production

Today's consumers are more safety conscious than ever, and when it comes to UHT (Ultra-Heat Treatment) milk processing, there is no room for error – the whole process has to be sterile. As the inventors of aseptic food processing technology, we offer the highest level of hygienic design – our solutions are proven to be the most reliable on the market. These ensure you get the highest possible food safety and milk standardization and cost-efficient production for both bulk and premium products.

What is UHT treatment?

Ultra High Temperature or Ultra Heat Treatment is used for the sterilization of low acid foods. UHT milk processing and treatment involves heating the product to over 135 °C. It destroys all microorganisms, making the end product suitable for ambient distribution.

Processing lines for UHT white milk

Best-practice line for UHT milk: direct heating

For premium or formulated products, we offer this direct UHT system. A low heat load means the end product has less of a ‘cooked flavour’.

Explore our best-practice lines for dairyBest-practice line for UHT milk: indirect heating

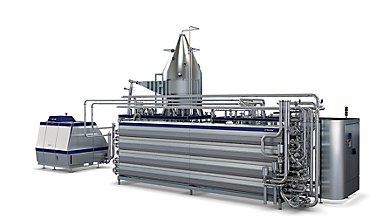

Designed for high operational efficiency, the Indirect UHT line incorporates our effective, durable tubular heat exchangers. Optimized processes extend your running times between cleaning (CIP and sterilisation). And thanks to a shortened mix phase, the line also reduces product losses.

Explore our best-practice lines for dairyBest-practice line for UHT milk: OneStep technology

This dedicated line for high volume production of ambient milk takes efficient production to a whole new level. It cuts down the number of processing steps in the dairy, thereby reducing your operational costs by 30 – 50%.

Explore our best-practice lines for dairyUHT treatment for dairy products

In UHT treatment, the goal is to maximise the destruction of microorganisms while minimising the chemical changes in the product. That means finding the optimal combination of temperature and processing time for different types of food.