Características

Magazine with horizontal tables

Boosts productivity and prevents injuries

The blanks are loaded in the magazine at an ergonomic height, so operators do not have to lift heavy loads over their heads. This enables fast and easy loading, thereby improving productivity. At the same time, it prevents operators from suffering back injuries. Magazine capacity: 1,400 packages. Production time: 13 minutes.

Package forming

Easy to adjust and maintain

The package is formed in a single step. When developing this forming mechanism, the objective was to achieve a simple and economical design, which would be easy for technicians to handle. Its simplicity and the reduction in moving parts, lead to a reduction in maintenance needs, and an overall improvement in reliability.

Bottom folding and sealing

Reliable bottom sealing enhances food safety

Temperature-controlled double heaters and mandrel tops, combined with an extended cooling period (long enough to cool down the bottom seal properly) result in reliable bottom sealing and enhances product safety.

Package transfer

Maintains package integrity

Once the bottom seal has been made, the package is transferred from the mandrels to the package chain. This is done gently in order to prevent the package from being damaged.

Top pre-folding

Increases folding accuracy

Before entering the next production step (package disinfection) the package is pre-folded. This preparatory folding helps to prevent errors in the final top folding and sealing.

Package disinfection

Ensures consistent disinfection

3.0% hydrogen peroxide (H202) in the form of hot vapour is applied to the inside of the carton. A nozzle reaches deep inside the package to ensure thorough coverage. The hydrogen peroxide is then activated by passing the cartons through three UV light stations. Lastly, hot air removes any H202 residues to an undetectable level. The result is a reliable and consistent level of disinfection.

Filling system

Increases accuracy and lowers costs

A double diaphragm system allows you to fill accurately and consistently. Filling accuracy is at most ± 1 gr per 1000 ml (actual standard deviation is 0.5 gr). This reduces the need for compensatory over-filling, and thereby helps keep costs in check.

Top sealing

High performance with tight seals

Mechanically driven stainless steel top sealers are engineered for consistent performance. The pressure and temperature of the seal are always the same, which ensures strong, reliable seals that do not leak.

Cap applicator

Consumer convenience

An optional integrated applicator can be used for TwistCap™ OSO 34 and TwistCap™ OSO 30 closures. The caps are applied using ultrasonic (US) heating, which gives a quick, tight and accurate seal, thus ensuring good product protection.

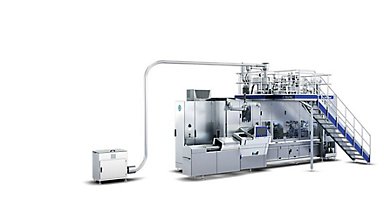

Tetra Pak TR/G7 da buenos resultados

La nueva Tetra Pak TR/G7 es una máquina de llenado de alto rendimiento, de bajo costo y fácil de operar para la distribución refrigerada.

La máquina Tetra Pak TR/G7, que cuenta con una capacidad de 6500 envases Gable Top por hora, proporciona beneficios medioambientales importantes en comparación con máquinas similares en el mercado; por ejemplo, consume un tercio menos de electricidad que las demás.

Para obtener más información, mire el video

Tetra Pak TR/G7 da buenos resultados

La nueva Tetra Pak TR/G7 es una máquina de llenado de alto rendimiento, de bajo costo y fácil de operar para la distribución refrigerada.

La máquina Tetra Pak TR/G7, que cuenta con una capacidad de 6500 envases Gable Top por hora, proporciona beneficios medioambientales importantes en comparación con máquinas similares en el mercado; por ejemplo, consume un tercio menos de electricidad que las demás.

Para obtener más información, mire el video