Why two-stage homogenization is best for tomato products

Almost all dairy producers use a two-step method to homogenize milk, but not all tomato ketchup or tomato paste producers do the same. That means they are missing out on the benefits: up to 20% increase in the lifetime of critical parts of the homogenizers. The savings in spare parts make the investment in a second homogenizer worthwhile in the long run.

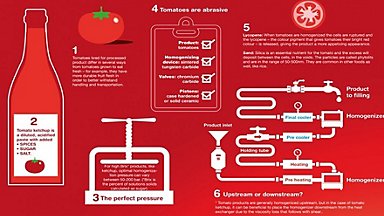

Tomato processors sometimes complain that the wear and tear on the homogenizer means they frequently have to change the working parts. Even though homogenizers are made of some of the toughest steels available, tomatoes are highly abrasive. Known to grow best on sandy soils, tomatoes contain silica, and the tiny fibres can be as hard as shards of glass.

Cavitation causing wear and tear

When the pressure drops inside the homogenizer from about 200 bar to 1 bar in a split second, cavities are formed in the tomato pulp. Cavitation (implosion of the cavities) is what degrades the tomato fibres to a paste, but it also causes wear and tear on the surface of the homogenizer.

However, there is a way of controlling cavitation by using a second homogenization step. The second homogenizer creates a steady back pressure on the first step of homogenization. The theory goes that the cavitation takes place in the bulk of the liquid, away from the walls, instead of next to the walls, as happens in one-step homogenization. This reduces wear.

Second homogenizing step

“Our experience from a large number of installations at tomato processing plants has shown that the accumulated wear will be substantially lower than in a one-stage homogenizer, giving up to 20% longer lifetime of the spare parts,” says Jenny Jonsson, Application Specialist at Tetra Pak Processing Systems.

She also tips producers about a trick to use: “When the parts in the first homogenizing step are showing signs of wear and need changing, you can take them out and install them in the second homogenizer step where they go on working for a long period before needing replacement. In this way, you can develop a very efficient maintenance programme that saves you money.”

Sign up to download the report Homogenization of tomatoes