Quick facts

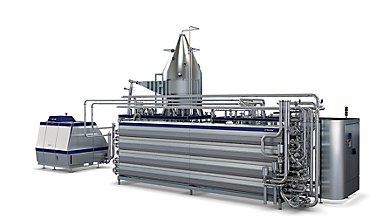

Continuous, gentle indirect UHT treatment unit with scraped surface heat exchanger for viscous products, with or without particles, that keeps sensitive product in motion

Capacity

1,000 – 1,500 l/h, others on request

Applications

Rice puddings and desserts

Features

Inline blending

Ensures product quality

Our uniquely accurate continuous blending give your products consistent quality. Exactly the right amount of rice is introduced into the milk at all times, and the particles are continuously and evenly distributed throughout the product. The result is a rice pudding with exactly the right texture and colour. The same applies to other desserts produced in this unit – mousses, custards, fruit preparations and cream cheese.

Advanced recipe handling

Safeguards product quality

As part of Tetra Pak®’s advanced automation system, cooking time, cooking temperature and filling temperature can all be pre-set. This makes it is easy to configure new recipes and prevents the risk of human error.

Tangential inlet

For product handling

The product flows naturally through the heat exchanger, thanks to a tangential inlet. Since no change of direction is necessary, there is very little impact on the product.

Built in scrapers

Ensure uniform heat transfer

Inside the heat exchanger, scrapers continuously remove product from the cylinder walls. This ensures uniform heat treatment, and prevents the product from fouling and thereby avoids a burned taste.

Integrated rotor lift

Facilitates inspections and maintenance

The heat exchanger is equipped with a built-in, hydraulically driven rotor lift. Easily operated by a handle to the side of the unit, this lift means that maintenance and service jobs can be performed quickly and safely.

Inline blending

Ensures product quality

Our uniquely accurate continuous blending give your products consistent quality. Exactly the right amount of rice is introduced into the milk at all times, and the particles are continuously and evenly distributed throughout the product. The result is a rice pudding with exactly the right texture and colour. The same applies to other desserts produced in this unit – mousses, custards, fruit preparations and cream cheese.