特点

不使用双氧水的灌装机

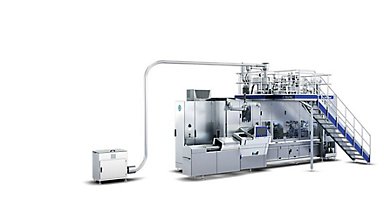

利乐® E3/紧凑柔性巴氏杀菌灌装机

利乐® E3/紧凑柔性灌装机适合冷藏产品,并且不需要对包装材料进行灭菌。只需要极少量的双氧水来对灌装机进行灭菌。

利乐® E3/紧凑柔性超净型灌装机

此型号的利乐® E3/紧凑柔性灌装机适合生产延长货架期产品,它采用一个电子束灯对包装材料内部进行消毒。只需要极少量的双氧水来对灌装机进行灭菌。

微型单头密封

更均一的密封质量

采用 Mini Single Head Compact Transducer 支持的超声波技术来对包装进行横向密封。它是一个使用单头而不是双头的新组件。这确保了更均一的密封质量,并将机器产能提高到了 9000 个包装/小时。

新的操作员界面

宽屏

操作员面板将具有新的外观和更宽的屏幕(长宽比为 16:9)。提供了更直观的图标,功能性更强,使用更方便。减少了执行各种操作所需的时间。

两个可选的清洗系统

选择全自动清洗或环保型清洗

客户能够在两个外部清洗选项之间进行选择,并且有机会定制自己的清洗周期!两个预先定义的可用选项为:

- 一个全自动过程,可确保清洗工作(包括清洗无菌仓)更高效。

- 一个耗水量低的、更环保的选项

清洗参数将显示在操作员面板上,这些参数可根据客户特定需求来进行定制。

卷筒位置主动控制

提高了密封质量并减少了灰尘

此新功能改进了灌装机功能的两个重要方面:

- 密封质量好,因为通过动态位置更正提高纸卷筒定位的准确性

- 减少了灰尘,因为设备不会与包装材料的边缘接触

突破性的电子束技术

利乐®E3平台是一系列使用电子束技术对包装材料进行灭菌消毒的灌装机,电子束技术能够替代传统的双氧水灭菌,且灭菌效果不亚于后者。电子束灭菌技术的工作原理是,在包装材料通过灌装机时,将一束受控的电子束聚焦在包装材料表面,从而杀死微生物。

观看视频,了解更多信息

突破性的电子束技术

利乐®E3平台是一系列使用电子束技术对包装材料进行灭菌消毒的灌装机,电子束技术能够替代传统的双氧水灭菌,且灭菌效果不亚于后者。电子束灭菌技术的工作原理是,在包装材料通过灌装机时,将一束受控的电子束聚焦在包装材料表面,从而杀死微生物。

观看视频,了解更多信息

电子束技术的优势

电子束

降低运营成本

突破性技术

电子束

改善环保绩效

生产灵活性

用于纸包装材料灭菌的电子束技术

* 相关资质证号:沪环辐证[60463]